- Product

Overview - Photo

Gallery - Video

gallery - Product

Specifications - Request

a quote

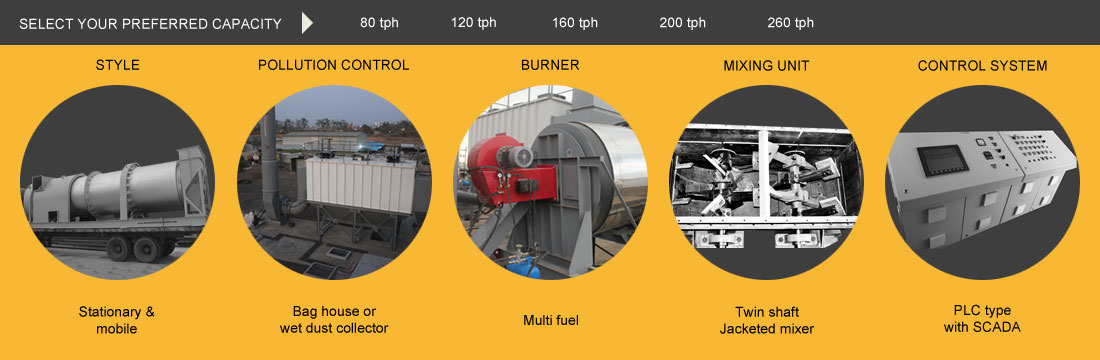

ABP range of asphalt mixing plant from India is containerized design offered by Atlas. We are looking forward asphalt batch mix plant of export in Bangladesh, Saudi Arabia, Kenya, Tanzania, Philippines and UAE. Considerable improvements in the old design makes it ideal and maintenance free for road contractors looking for reliable and sturdiness. Better knowledge of the product and track record of proving excellent service support to customers in India and abroad makes Atlas. Asphalt mixing plant is available in three capacities 80 tph, 120 tph and 160 tph. Capacities above 160 tph are also available and are tailor made.

Atlas Asphalt Mixing Plants Advantages:

Atlas asphalt mixing plant for sale comes with host of features and simple to use design. The simplicity of the design allows customer to focus on his job as the plant is capable of doing its job with ease. Low maintenance design ensures high productivity even after years of use.

- Containerized design helps in reducing the transportation cost drastically.

- Built on a rugged and strong structure - suitable for rough operating conditions.

- The tower unit is on skid mounted plates. Other units can also be made available on skid plates on request of customer.

- This asphalt mixing plants from India can easily be considered as one of the better designs in terms of low maintenance and low operating costs.

- High efficient and low noise multi fuel burner unit is what you need.

- Thermally insulated drying drum with option for friction drive and chain drive available.

- Modular units are designed for easy transportation and fast installation of the equipment.

- Modular design also allows easy loading into containers and easy unloading at customer’s site.

- Total seven pneumatic cylinders used in the machine all of same size so spare management is easy – we are asphalt mixing plant manufacturers whose focus is on customer care.

- Bitumen weighing system is much simpler than the old design making it more energy efficient.

- Maintenance of the cylinders mounted on hot bins is very easy now.

- Mixing unit comes with planetary gear boxes on each shaft for better performance and torque absorption.

- Minimum civil work required has to be done at site.

- New bag filter design comes with 3 rotors for cleaning efficiency.

- We do use standard materials in the manufacturing.

- The control panel of the asphalt mixing plant for sale is designed for ease of operation.

- Screen sizes can be customized as per your requirement.

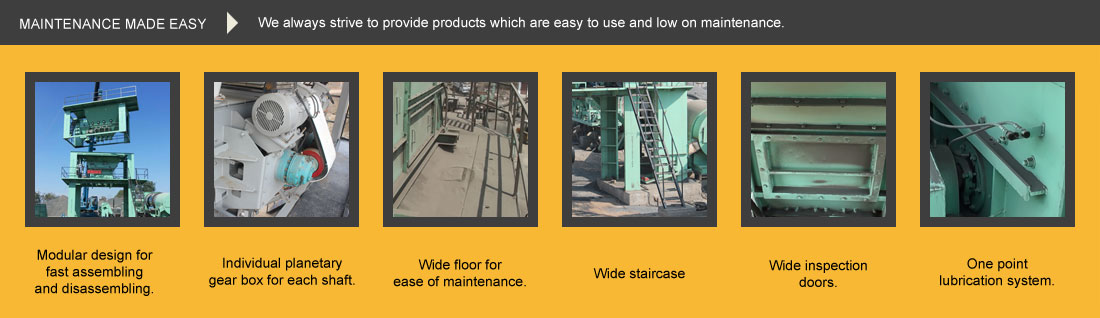

- Ease of access for fast maintenance helping you to achieve maximum productivity.

- This equipment is also available with venture type wet dust collector in place of bag filter unit for pollution control - for countries where pollution control norms are less stringent.

- The cost of the spare parts is the lowest in the industry.

- Extremely user friendly PLC control panel provides option to store various types of hotmix recipes with possibility to change the recipes frequently.

The focus of Atlas when we developed this design was to improvise on the existing machine while making sure that the new plant is low on running cost, low on maintenance and is affordable to own. We did not want to increase the cost factor while improving the design. The new machine is easy to use as it comes with PLC panel. The units are all modular which makes assembly and start up very fast. The tower unit comes on skid mounted plates so that minimum foundation is required at the site and normal levelling of the land will suffice.

The cost of this containerized design asphalt mixing plant is much lower than what the competition has to offer while this equipment is much easier and low cost when we compare the maintenance factor. You can rely on it for quality hot mix asphalt and simultaneously expect it to perform continuously for years to come.

The standard configuration for asphalt hot mixing plant includes:

Atlas make asphalt hot mixing plant comes complete in all aspects. All the components are manufactured with care and precision. All components in synchronization will ensure that the plant works on maximum output to deliver optimum results.

- Cold feeder bins

- Primary scalping screen

- Charging conveyor

- Drying drum with burner unit

- Elevator to take hot aggregates to the tower unit

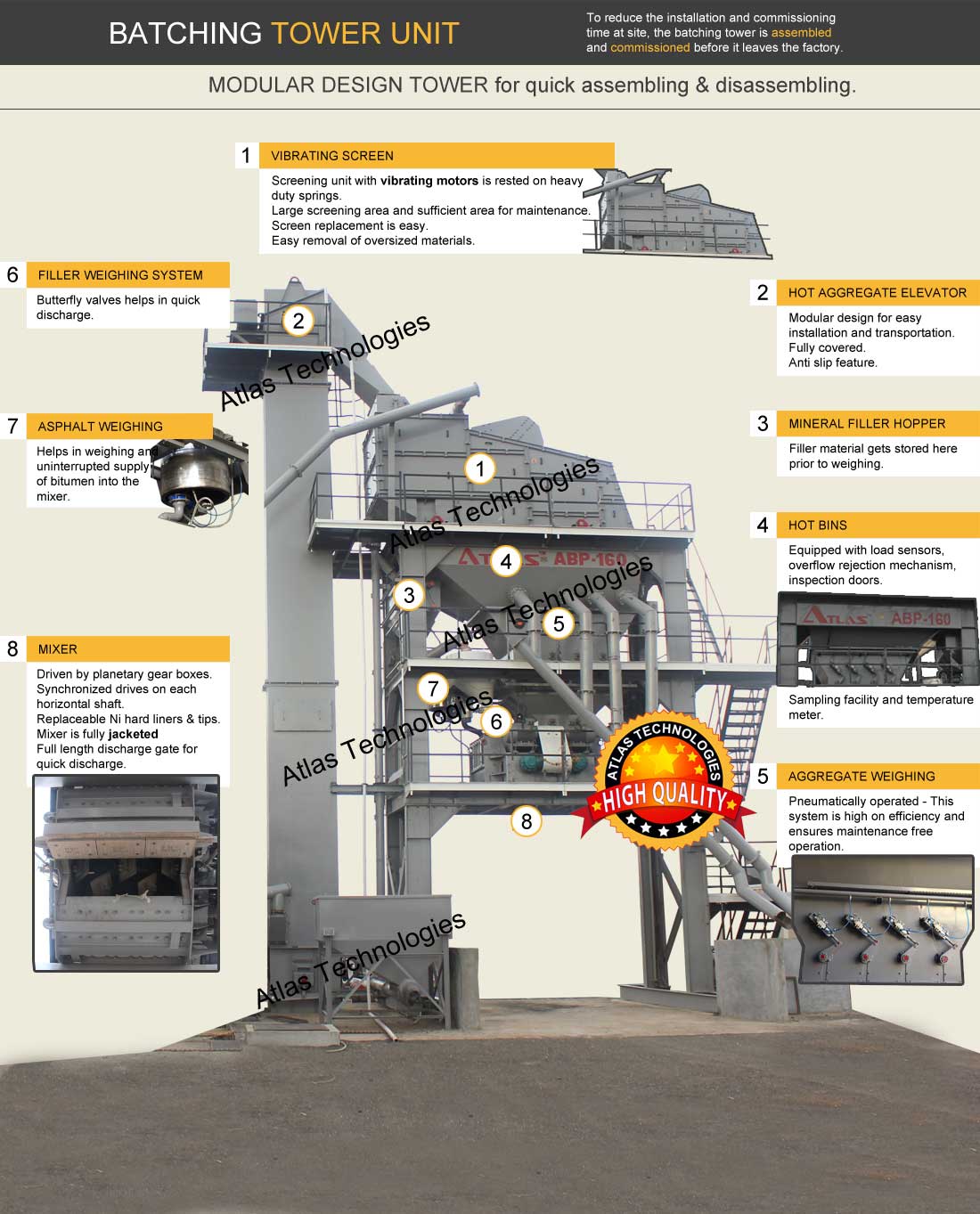

- Tower unit comprises of vibrating screens, hot bins and mixing unit. Tower unit also houses weighing bins for filler and bitumen.

- Bitumen tanks with hot oil system for heating bitumen and jacketing the mixing unit.

- Filler hopper / silo with screw conveyor /elevator.

- Bag filter unit with pre-separator

- Control panel system for the asphalt hot mixing plant.

Components of the asphalt mixing plants are:

Atlas make asphalt mixing plant are manufactured with care and precision. These asphalt batch mixers are designed keeping the end user in mind. Each component is tested for durability. It promises years of service with less maintenance. Many customers have benefitted by using this machine and compleated their projects on time.

Hot aggregate bucket elevator: Fully enclosed unit - the bucket elevator for hot aggregates take the aggregates from the drying drum below to the vibrating screen on top of the tower unit. It is supplied with wear plates, drives (electrical and mechanical) and wiring.

Mineral filler feeding system: The standard configuration comes with filler hopper and screw conveyors for feeding the filler material into the filler hopper.

With the asphalt mix plant India, an optional filler elevator can also be provided. It helps in transferring the minerals from the filler storage bins to the filler weigh hopper situated on the tower unit. The level indicator on the dust storage bin controls the flow of filler from filler elevator. This unit is fully enclosed bucket type elevator system.

Vibrating screen: The vibrating screen is four decked and is for separation of different types of aggregates. Screen sizes can be customized as per the requirements of the customer. The scalping screen of Atlas asphalt mixing plants for sale is big giving a large enough screening area so that aggregates can move quickly and uninterrupted flow is aggregates is achieved. It is inclined and vibrating type which is rested on spring absorbers.

There is enough space near the screening platform which makes maintenance easy. The screen replacement is also easy making the module one of the easiest to maintain. Screen design allows for quick removal of the oversized aggregates.

Hot aggregates storage bins: The number of hot bin compartments is the same as the number of vibrating screens. Hot bins will store aggregates into separate compartments after the screening process is over. The asphalt mixing plant for sale comes with storage of aggregates here is only for short time till they are discharged by pneumatic gates for weighing. There will be sampling facility on each bin. This section of the tower asphalt mixing plants is also equipped with load sensors mechanism to reject overflowing aggregates.

Aggregate weighing system: The aggregate weigh hopper is for weighing aggregates. It will receive aggregates one by one for weighing prior to discharge into the mixing unit. It is suspended on four load cells. Once the weighing of all the aggregates is complete, the aggregates are discharged into the mixer. The discharge is by opening of the gates pneumatically.

Filler weighing system: Filler here reaches by screw conveyor. The weigh hopper for filler is suspended on load cells and is equipped with butterfly valves for quick and efficient discharge of the filler material into asphalt mixing unit by gravity.

Bitumen weighing: Bitumen from the storage tanks below is transferred by the help of transfer pump. The weigh tank is circular and fully insulated on all the sides to prevent heat loss. Weighing tank will store bitumen prior to the discharge into the mixing unit. As soon as the bitumen is weighed, it will be transferred by gravity into the mixing unit.

Asphalt Mixing unit: Twin shaft type mixing unit is a fully jacketed unit powered by planetary gear boxes for individual shafts. Asphalt mixing unit is a tried and tested unit which is known for smooth and trouble free operation. The system allows homogenous mixing of aggregates with bitumen and filler material in quick time. The liners, arms and tips are designed for long life and are easy replaceable. The gate is pneumatically operated and is full length. It helps in quick discharge of the hot mix asphalt. There is sufficient space on the mixer platform for easy maintenance.

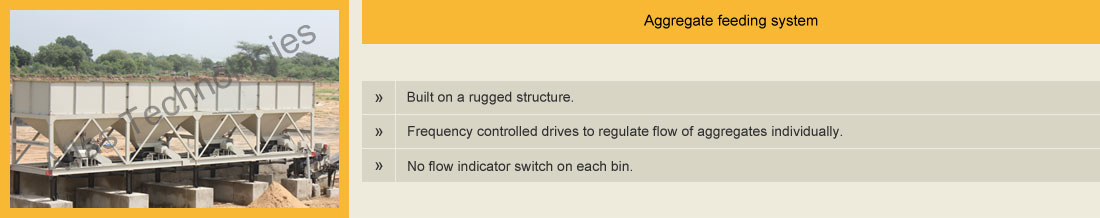

Standard unit of the cold aggregate feeder unit is four bin type. The modular unit feeder bin of the asphalt mixing plants can be easily transported. It can be customized to suit customers requirement as the number of bins can be more or less depending on customer’s requirement. With the standard configuration, one bin comes with vibrating motor. This vibrating motor can also be fitted on more bins if required. Each feeder bin comes with adjustable radial gate for discharge of materials. It is also equipped with variable speed drive to adjust the feed of the bins individually. Each bins is provided with endless auxiliary belt with head and tail pulleys, idler rollers, belt tensioners, rubber skirting (replaceable). Each bin also comes with no flow indicator switch so that the operator can be intimated in case there is lack of material in any specific bin.

With the Atlas asphalt mixing plants for sale the endless type gathering belt runs through the bottom of the feeding unit and it collects all the aggregates and transfers them to the primary scalping screen.

After screening the aggregates they are transferred to the drying drum by the charging conveyor. This conveyor is on a rigid frame.

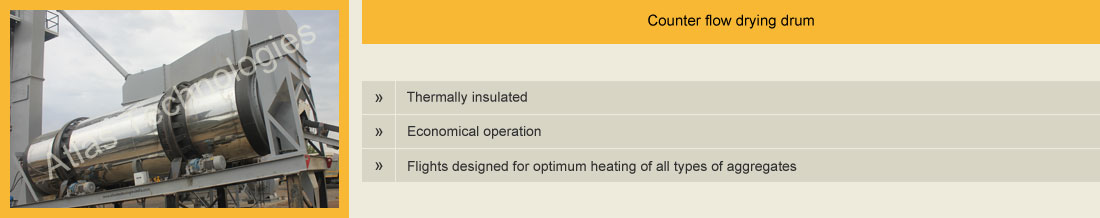

The drying drum is cylindrical and placed inclined. Aggregates enter the higher end of the drum and pass through the lower end of the drum. In the process they get heated. The flights are designed for maximum thermal efficiency and to make maximum use of the burner heat for heating the aggregates. If the customer demands we can cover the drum on all sides by heat resistant material and by SS coating which is very good for resisting the heat from escaping the drum.

There are many asphalt mixing plant manufacturers India but very few manufacturers lay emphasis on quality and provide as many options. Our drum is laid on four drum rollers and can be friction drive type. Drum can also be chain driven depending on customer’s requirement.

Maintenance of the drum is very easily accessible. There is a temperature meter on the discharge chute of the drum.

Burner unit is fully automatic, modulating, high pressure, low noise and multi fuel type (Diesel/LDO). The burner is very carefully designed so that maximum thermal efficiency is achieved in the heating process. This unit can also be modified to work with FO also.

Burner unit is fully automatic, modulating, high pressure, low noise and multi fuel type (Diesel/LDO). The burner is very carefully designed so that maximum thermal efficiency is achieved in the heating process. This unit can also be modified to work with FO also.

Pre separator with the bag filter ensures that heavy dust particles are trapped in before they enter the bag filter unit. Dust is sucked in from the vibrating screen. There is also provision to recycle the dust back into the tower unit by feeding it at the foot of the elevator.

The asphalt mixing plant for sale comes with either venture or bag filter unit for pollution control. Ventury type wet dust collector unit uses water to entrap larger dust particles by treating them to cyclonic effect and entrapping them.

Bag filter is the dry type pollution control device. It is a reverse air flow type unit with three rotors on the top of the unit for cleaning the bags regularly. The filter area is sufficient with high quality bags doing the cleaning efficiently. The rotors on top of the bag filters clean only 8 bags at a time which makes the cleaning process very efficient and increases the life of the bags.

Asphalt storage tanks in Atlas asphalt mixing plant are usually two in number and horizontal type. The heating system used is indirect heating system by the use of thermic oil which is heated in a separate thermic oil heater unit. The coils from the thermic fluid heater run through the internal of the bitumen tanks thus helping in heating of the bitumen. These tanks are fully insulated from all the sides with temperature indicator.

Thermic oil heater comes with automatic light oil burner for heating the internal coils through which the hoi oil passes. Bitumen pipelines are fully jacketed to prevent heat loss.

Vertical fuel storage tanks are provided with the Asphalt mixing plant. These tanks can be one or two in number if different fuels are used or more storage of the same fuel is desired. The tanks come with fuel transfer pump, piping and necessary controls.

PLC touch screen control panel is a breeze to use. The control panel is designed with care and for ease of operation. Coloured display makes all the relevant information clear to read. The components used in the manufacturing of the control panel of the Atlas hot mix plant are all standard make. Optional SCADA based system is also available.