- Product

Overview - Photo

Gallery - Video

gallery - Product

Specifications - Request

a quote

Atlas is manufacturer of mobile asphalt batching plant from India. This small asphalt mixing plant is truly mobile in all aspects. Some of the primary advantages are that portable batch mix plants machine can be erected and made to make hot mix asphalt in 48 hours. This equipment is advantageous for those contractors who want to move very often. It is also foundation less design that promises low maintenance. The design is reliable and chassis is sturdy. Atlas has sold and installed more than 70 asphalt batching mixing plants in 3 years. Superior product knowledge, customer centric approach while developing this product allows us to develop a product which is superior in many aspects. This is a containerized design available in 80 tph, 120 tph and 160 tph. Capacities above 160 tph are tailor made.

Mobile Hot Mix Plant Layout

The layout of Atlas mobile hot mix plant is simple. This mobile batching plant is perfect if you want to shift sites very often. All the chassis are arranged in such a way that maximum space saving is possible. Adequate space for maintenance is left. All the units are modular and fully mobile.

- Mobile cold feeder bins

- Single deck primary vibrating screen

- Slinger / charging conveyor

- Mobile drying drum with burner unit

- Mobile tower unit comprises of bucket elevator, vibrating screen unit, hot bins and twin shaft type mixing unit. Weighing bins for filler and bitumen is also included in the tower unit.

- Control panel of the mobile hot mix plant is on the same chassis of the tower unit.

- Mobile bag filter unit with pre-separator.

- Bitumen tanks with hot oil system for heating bitumen and jacketing the mixing unit are also mobile.

- Filler hopper is also mobile.

- Filler silo with screw conveyor /elevator can also be provided instead of filler hopper.

Our main aim is to present mobile design which is modular and faster to install without use of big cranes. We did not want to compromise on the transportation factor and hence the units are containerized. This is the same version of the already successful Atlas stationary asphalt batch mix plant. The sizes of the units are not compromised to focus on the mobility. This means that customers are getting a full fledged mobile plant which performs like its stationary version. The design is low on maintenance and it also has sufficient space for maintenance. The structure is heavy and cost price of the equipment is affordable. It comes with the same control panel features. Foundation less design is ideal to move sites quickly.

The cost of this containerized mobile asphalt batch plant is lower than what others offer. It is also easy to use and low on maintenance. We have kept the cost of spare parts low because the plant should be economical in the long run. You can expect it to give faster return on investment.

Advantages of Mobile Batch Mix Plant For Sale

The Atlas mobile batch mix plant for sale has many advantages. It is ideal batching mixing plant that is rugged. It is also maintenance free design that promises low operating cost. If you are looking to buy a quality mobile asphalt plant look no further than this equipment for sale.

- The equipment’s fully containerized design helps to reduce the transportation cost. This is ideal for customers who want to shift sites more often.

- The plant is build on a rugged and strong structure. It is suitable for rough operating conditions. All the units are strong and are designed to last long.

- This is a foundation less design so a lot of time is saved.

- The plant can be commissioned by use of 1 hydra crane.

- This mobile asphalt mix plant from India manufacturer is one of the better and simple designs as far as mobility is concerned.

- Low maintenance and low operating costs.

- Proven, high efficient and low noise multi fuel burner unit is provided.

- All the units are modular. It is designed for easy transportation and fast installation.

- Installation can be completed in 48 hours.

- Easy loading into containers and easy unloading at customer’s site. Reason is modular design of the machine.

- Bitumen weighing hopper and filler weigh hopper are near to the mixing unit. Both of them fall into the mixer by gravity.

- Atlas mixing unit supplied with this mobile asphalt mixer comes with planetary gear boxes. These gear boxes are fitted on each shaft. They aid in better performance and better torque absorption.

- Very less civil work is required at site and this helps to save a lot of time.

- New bag filter design comes with 3 rotors for cleaning efficiency.

- All the materials used are of standard make.

- The control panel is on the same chassis along with the tower unit. The software is easy to use.

- Vibrating screen is available in different sizes. It is possible to customize the sizes as per your requirement.

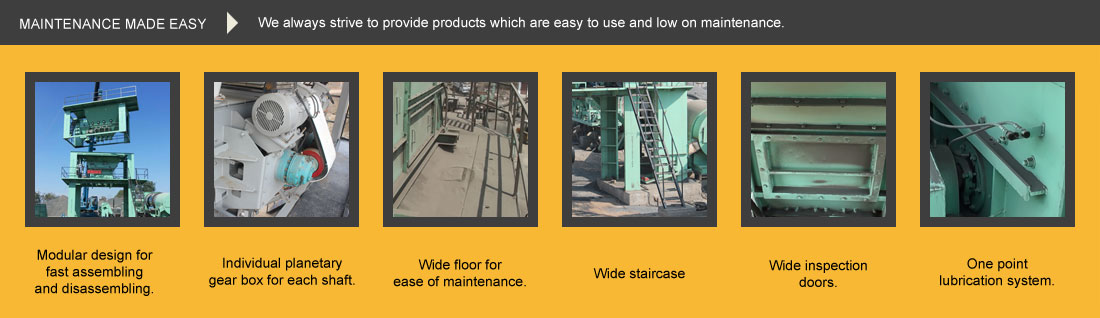

- Adequate space is available near the components making maintenance easy and fast.

- We have kept the cost of the spare parts very low.

- The PLC control panel is user friendly. It provides option to store various types of hot mix recipes. It is also possible to change the recipes frequently.

Components of Mobile Asphalt Plant From India

This mobile asphalt plant from Atlas is manufactured at our factory in India. The components of mobile asphalt batching plant are designed in such a way that mobility is achieved without any compromise in production. The components are adequate and not smaller in size.

Components of the asphalt plant are as below:

Mobile cold aggregate feeder

The standard configuration of mobile cold aggregate feeder has 4 bins. This unit is fully modular and comes on its separate chassis with axle. It can be easily transported. The number of bins can be more or less to suit customers requirement. One feeder bin is provided with a vibrating motor for free flow of sand. Every feeder bin comes with radial gates for material discharge. This also allows us to open the gate fully or partially as required. Each gate also comes with a variable speed drive motor to adjust the speed of each feeder bin. No flow indicator switch is standard on each bin. Each bin is provided with auxiliary belt, head and tail pulley for auxiliary belt. Idler rollers, belt tensioners and rubber skirtings are provided.

The gathering belt is big and it runs through the bottom of the feeding unit. It will collect all the aggregates and transfers them to the primary scalping screen.

After screening the aggregates, they are transferred to the drying drum by the charging conveyor. This conveyor is on a rigid frame.

Mobile drying drum of hot mix plant

The drying drum of the hot mix plant is also mobile on its separate chassis. It is a cylindrical unit which is inclined and placed at a degree for free flow of aggregates. Aggregates will enter the higher end of the drum. Aggregates will exit the lower end of the drum. as the aggregates pass from one end to the other they will get heated. Flights are fitted inside the drum. They will help to evenly heat the aggregates as they pass through the drying drum.

There are many asphalt hot mix plant manufacturers in India but only few put emphasis on quality. The drying drum is a critical component and its combination with a good burner will work wonders for the machine. The drum is laid on four rollers. It can be chain driven or friction wheel driven. Maintenance is easy

Multi fuel burner

Burner unit fitted on the drum unit is fully automatic. It is high pressure, low noise, modulating and multi fuel operated. The burner compliments the drying drum and is very carefully designed. We have made sure that maximum thermal efficiency is achieved in the heating process while using minimum fuel. If required, the burner unit can also be modified to work with furnace oil.

Pollution control system – Mobile bag filter

Bag filter provided is also mobile and on a separate chassis. Pre-separator does the task of trapping the heavy dust. Lighter dust particles will be trapped by the bag filter unit. The filtration area of the bag filter is sufficient and it does the job well.

It is also possible to have venturi type wet dust collector for pollution control. It will use water to trap the dust particles.

Mobile bitumen storage tanks

Bitumen tanks provided with Atlas mobile batching plant are mobile type. The number and size of the tanks can be customized by the customer. Usually customers prefer two bitumen tanks – the capacity may vary. The heating system is indirect heating type.

Asphalt storage tanks in Atlas asphalt mixing plant are usually two in number and horizontal type. It is indirect heating type system. It uses thermic oil for heating the bitumen. Tanks are fully insulated from all the sides with temperature indicators.

Mobile fuel storage tanks

Mobile fuel storage tanks can be provided with the portable asphalt batch plant for sale. The tanks can be more in number if more fuels have to be used. They come equipped with piping, fuel transfer pump and necessary controls.

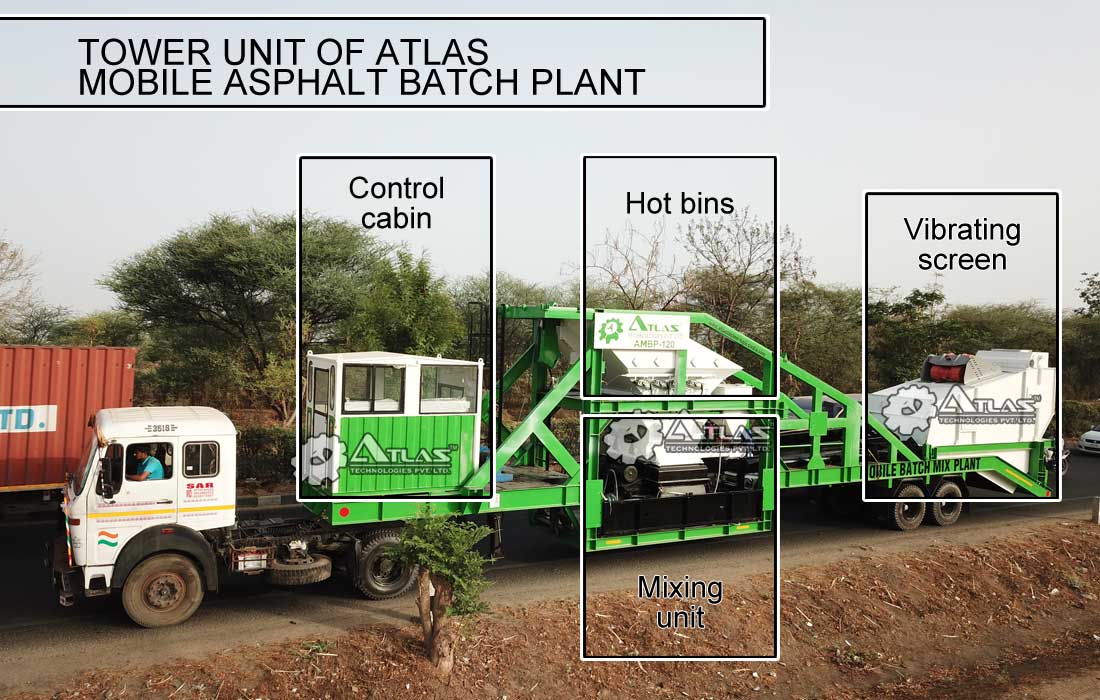

Mobile tower unit for asphalt plant

Mobile tower unit of the asphalt plant consists of many components. All these components are arranged in such a way that maximum mobility is possible. The components can be made to set up quickly and the plant can be made to run in quick time.

-

Hot aggregate bucket elevator

The bucket elevator unit is in the same chassis of with the tower unit. It is a fully enclosed unit for transfer of heated aggregates form the drum to the vibrating screen. The bucket elevator gets folded while transportation as it is on a center pin. Within a short time the bucket elevator can be fitted.

-

Mineral filler feeding system

The asphalt mixing plant is equipped with filler hopper and screw conveyors for feeding the filler material into the filler hopper. An optional filler storage silo can also be provided if required.

-

Vibrating screen

The vibrating screen is with sliding mechanism. It is possible to slide the screening unit to a side while transporting the tower unit. This mechanism makes it very easy for the plant to go mobile in short time. Vibrating unit is four decked for different types of aggregates. It is possible for the screen sizes to be different as per different customers needs. The screening area is large so that screening process is quick. The screens are inclined and vibrating type rested on shock absorbers. Screen replacement is very easy.

-

Hot aggregates storage bins

This compartment is just below the screening unit. The number of hot bins compartments is the same as the number of vibrating screens. After the screening process is over, the hot bins will store aggregates into separate compartments. The mobile asphalt plant for sale will store the aggregates in the hot bins for short time. They will be discharged for weighing by opening of pneumatic type gates.

-

Aggregate weighing system

Here we will weigh the aggregates before they will be discharged into the mixing unit. Aggregate weigh hopper will receive the aggregates one by one for weighing. After the weighing of each bins is over they will be discharged into the mixing unit. This weighing system is suspended on load cells. The open-close gates are pneumatically operated.

-

Filler weighing system

Filler weighing system is suspended on load cells. It is on the same chassis of the tower unit near the bitumen weighing system. Filler material will reach here by a screw conveyor. It is equipped with load cells and with a butterfly valve for fast discharge of the materials into mixing unit.

-

Bitumen weighing system

Bitumen weighing system consists of a bitumen weigh tank. This is suspended on load cells. Bitumen from the bottom is transferred to the weighing tank by means of a transfer pump. This tank is insulated on all the sides to curb heat loss. This tank will store bitumen before discharging the same into the mixing unit.

-

Mixing unit

Mixing unit is just below the hot bins. It will receive hot aggregates, bitumen and filler material for weighing. It is a fully jacketed unit which is fitted with 2 shafts. Each shaft is fitted with 2 planetary gear boxes. It is a tried and tested unit that promises trouble free operation. It allows homogeneous mixing in quick time. The liner plates are easy replaceable. Arms and tips are also easy replaceable. The mixer unit has sufficient space surrounding itself so that routine maintenance can be carried out easily.

-

Control panel

The control panel is housed inside a control cabin. Control panel is PLC touch screen type with easy to use colour display. The components used in the control panel of mobile batch mix plant are of standard make. SCADA type panel will be easy for you to access the important data of the plant from anywhere in the world.