- Product

Overview - Photo

Gallery - Video

gallery - Product

Specifications - Request

a quote

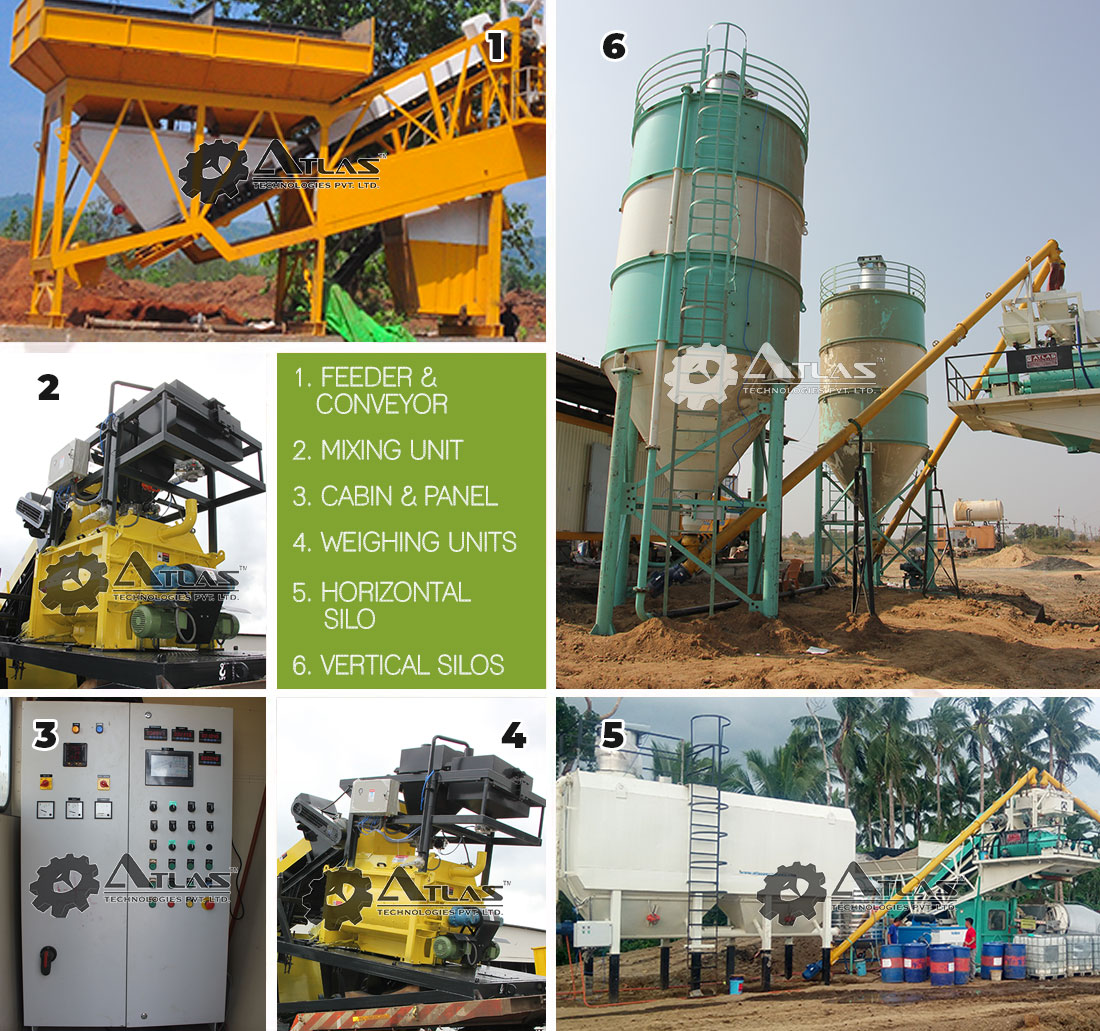

Get best mobile concrete batch mix plant from reputed and leading Indian supplier. Atlas is known for manufacturing and exporting wide range of batching plants. Our range includes capacities starting from 20 m3/hr. to 75 m3/hr. The other offered capacities in this design are 30, 45 and 60 cbm per hour. The main structure of the machine is on a single chassis allowing maximum mobility on wheels. The machine is easily towable and offers superior mobility. The advantage of fast installation and set-up of this rugged equipment is the hallmark of the equipment.

Users benefit from our years of experience and several installations across different countries. Our products are easy to use and updated regularly for best performance and weighing accuracy. If you need maximum mobility this concrete batch mixer from Atlas is your answer. It has performed in several key applications like construction of airports, bridges, dams, roads, buildings, etc. The performance-oriented design without compromising on the mobility factory allows for quick moving between the different sites.

The machine is prewired and comes with a foldable control cabin, setting up is very fast and requires minimal efforts. The production is at par with the stationary plant and the space required for installation is less. Control panel is easy to use with PLC and touch screen display. There is option to save, edit several recipes in the control room. Pan mixers or twin shaft mixers are available in this design.

|

Model |

AMCB 20 |

AMCB 30 |

AMCB 45 |

AMCB 60 |

AMCB 75 |

|

Capacity |

20 m3/hr. |

30 m3/hr. |

45 m3/hr. |

60 m3/hr. |

75 m3/hr. |

Capacities above 75 m3/hr. are tailor-made.

AGGREGATE FEEDER

The 2 x 2 bin design of aggregate feeders help save a lot of space. It also allows to make this a truly mobile type of concrete batching plant. There is sufficient storage of aggregate space in each of the 4 bins. Vibrating motor on the sand bin allows free flowing of the aggregates.

WEIGHING-CHARGING CONVEYOR

There is a single weighing conveyor for aggregates. It starts from beneath the aggregate bins. Weighing is very accurate with this conveyor. This conveyor will take the aggregates up to the mixing unit.

AIR COMPRESSOR

Air compressor of suitable capacity is provided with the Atlas mobile concrete batch mix plant. It is for controlling all the pneumatic operations of the plant.

MIXING UNIT

The standard mixing unit provided with Atlas inline concrete batching plant is the twin shaft type. Customer also have the option to choose from pan mixers or planetary type of mixer designs. It will receive the aggregates from the weighing cum discharge conveyor. The mixer is fitted with Ni hard liners for long life of the equipment. Arms, tips and liner plates are easy replaceable.

Mixer is on a heavy platform and it does homogeneous mixing in a short period of time. The mixer unit will receive aggregates, cement and water for a specific mixing time. Quality mixing units will ensure optimum mixing in a short period of time.

WEIGHING UNITS

Weighing is accurate and hence the plant can boast of superior mixing quality. Weighing units are separate each for cement, water and additives are provided. Cement weigh hopper is suspended on 3 load cells. Water tank with water inlet pipe and hanging on loadcells is provided with a rubber gasket at the bottom. Additives inlet comprises of admixer flask of suitable capacity with a feeding pump.

CONTROL CABIN AND CONTROL PANEL

Fully automatic PLC type control panel is housed inside the control cabin. Control cabin in portable concrete batch mixer is folding type and does not need any special foundation. All important parameters of the plant are controlled from the panel. It also allows adding and using recipes for the plant. All important mix material data is shown in the panel. There is provision for printing and with SCADA (optional in some models) the plant’s panel can be remotely accessed for online troubleshooting. Auto as well as manual operation in this concrete plant is possible.

CEMENT SILO / HOPPER

The standard plant is offered with cement hopper for addition of cement that is delivered in bags. The hopper provided is of adequate capacity and with a screw conveyor for transfer of cement on top of the mixer unit. Cement silos are very helpful in the bigger capacity batching plants. We offer various capacity of cement silos from 50 tons to 200 tons.

HORIZONTAL CEMENT SILO

Horizontal cement silos are available with Atlas in different capacities like 30 tons and 40 tons. The low height of the horizontal cement silo is an advantage as they take up less height compared to the traditional silo’s.

TRANSPORTATION

Transportation is super easy for this design of batching plant. It is compact design allows quick and easy movement and site shifting. The pneumatic braking system and king pin attachment is very helpful.