Asphalt Mixing Plants

Precision Asphalt Mixing Plants for Perfect Roads – From Artics to Sahara

Overview

Where Engineering Meets Pavement Perfection

For over three decades, Atlas Technologies has been a trusted name in asphalt plant manufacturing and supply. With over 2000+ installations across 35+ countries, our plants have paved highways, airports, and industrial roads worldwide. From high-volume stationary batch plants to rapid-deployment mobile units, our designs support up to 30% RAP integration and deliver consistent performance in tough environments.

Stationary Asphalt Batch Plants (ABP)

- Capacities: 60–320 TPH

- Features: Twin-shaft mixers (1,000-5,000kg batches), high weighing accuracy

- "The gold standard for high-volume highway construction"

Mobile Asphalt Batch Plants (MABP)

- Capacities: 80–160 TPH

- Features: Quick-relocation design, 72-hour setup

- "From jungle bases to mountain roads – mix anywhere"

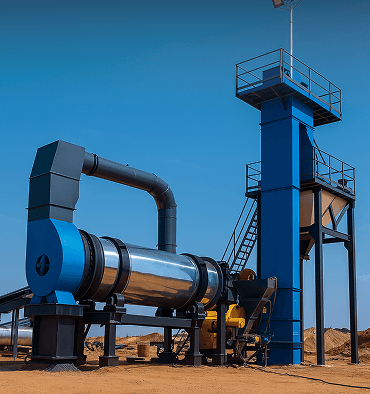

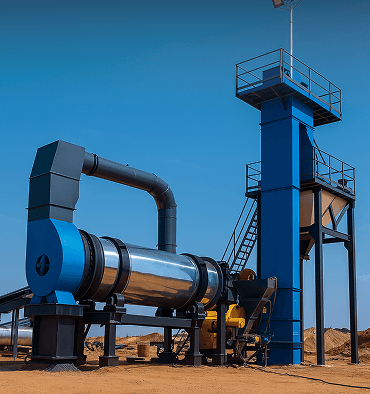

Double Drum Asphalt Plant

- Capacities: 40–150 TPH

- Features: Parallel-flow drums, optimized fuel efficiency

- "Where continuous production meets eco-conscious operations"

Counter Flow Asphalt Plant

- Capacities: 40–150 TPH

- Features: Reverse airflow technology, up to 30% RAP compatibility

- "Urban-ready: Low emissions without compromising output"

Asphalt Drum Mix Plant

- Capacities: 20–200 TPH

- Features: Single-drum simplicity, PLC-based automation

- "The workhorse for rural highways and industrial zones"

Mobile Asphalt Drum Mix Plant

- Capacities: 20–150 TPH

- Features: Trailer-mounted, ≤48hr deployment

- "Emergency repairs or remote projects – ready when you are"

BENEFITS

What Sets Atlas Asphalt Mixing Plants Apart

Latest Construction Technology

−Equipped with high-efficiency burners, PLC-based controls, and optional RAP systems supporting up to 30% integration.

Flexibility in Plant Mobility

+Choose from mobile or stationary configurations. Add-ons like liquid additive dosing and RAP modules are tailored to specific mix needs.

Global Support and Reliability

+With installations in 35+ countries and round-the-clock support, we ensure reliable uptime and fast-response service globally.

Sustainability and Efficiency

+Advanced bag filters and energy-efficient components reduce emissions and power usage, helping meet environmental standards.

Proven Track Record

+With over 35 years of experience and more than 2000+ plants running in India alone, Atlas Technologies is trusted by contractors worldwide.

CONNECT WITH US

Ready to Build? Let’s Talk!

At Atlas Technologies, we’re more than equipment suppliers—we’re your partners in infrastructure success. Whether you’re planning a highway project or upgrading your asphalt production, our team of experts is here to help.

Frequently asked questions.

1. What are the key factors to consider when choosing an asphalt mixing plant?

−When selecting an asphalt mixing plant, prioritize capacity, mobility, and sustainability features. Ensure the plant matches your project size (e.g., 20 TPH for small projects or 320 TPH for highways), offers flexibility (stationary or mobile), and integrates eco-friendly technologies like low NOx burners and RAP systems to reduce emissions and costs.

2. How can I reduce operational costs with an asphalt mixing plant?

+To reduce costs, choose a plant with energy-efficient burners and RAP integration (up to 30%) to minimize fuel consumption and raw material expenses. Additionally, opt for modular designs that save on installation and transportation costs, ensuring long-term savings.

3. What maintenance tips can help extend the life of my asphalt mixing plant?

+Regularly inspect and clean critical components like the burner nozzles, screen sieves, and elevator chains. Use wear-resistant materials for parts exposed to high abrasion, and follow a preventive maintenance schedule to avoid unexpected breakdowns and ensure consistent performance.

4. How does Atlas Technologies support clients after purchasing an asphalt mixing plant?

+Atlas Technologies provides 24/7 emergency support and quick access to spare parts, ensuring minimal downtime. Our team also offers training for operators and seamless software upgrades through our PLC-based systems control panels, helping clients maximize plant efficiency and productivity. That’s why we are among the top choice for asphalt plant manufacturing and distribution in India and across the world.