A Comprehensive Guide to Concrete Batch Plants

2025-02-18

Concrete is the main building material on which the reliability and durability of the whole building depends. Have you ever wondered how this concrete material stays rigid and strong? The answer lies in the concrete batch plant. A concrete plant also known as a static batching plant or batch plant produces concrete by mixing raw aggregates, sand, cement, additives and water It acts as a distribution centre where these materials are mixed in a mixer and disposed truck to customers. Main part of the plant is the mixing unit. As the name suggests it will mix all the items inside it for a fixed period of time.

Essential Components of Concrete Batch Plants

A concrete batch plant is formed due to many components that work together to make the plant run efficiently. They run together to ensure that the plant produces concrete efficiently and meets the required standards.

- Aggregate Bins: These are big storage containers that hold various sizes of aggregates.

- Cement Silos: These containers store cement.

- Weigh Batchers: These are precise systems that measure each ingredient exactly according to the mix design.

- Mixer: The core component that blends all ingredients thoroughly to make a consistent concrete mix.

- Control System: It’s the central control that automates the entire process.

- Conveyors: It is none other than buckets or belts that move ingredients from bins to weigh batchers and mixers.

Different Kinds of Concrete Batch Plants

Concrete batch plants are designed in different ways to match different project needs and production sizes. Here are the most common types:

- Stationary Batch Plants: The portable batch plants are mounted on trailers for easy transport. These plants are perfect for medium to smaller projects or those requiring frequent relocation. They are usually less expensive compared to stationary batching plants.

- Portable Batch Plants: The portable batch plants are mounted on trailers for easy transport. These plants are perfect for medium to smaller projects or those requiring frequent relocation. They are usually less expensive compared to stationary batching plants.

Select the Best Concrete Batch Plant

Choosing the right concrete batch plant requires careful consideration of several factors:

- Production Capacity: This is the basis of selection of a concrete batch plant.

- Project Duration: For long-term projects, a stationary plant might be more economical. Portable plants are better suited for shorter projects or those with frequent site changes.

- Site Conditions: The available space at the construction site will influence your choice. Compact plants are ideal for confined spaces.

- Concrete Mix Design: The type of concrete your project requires might influence the plant’s features. Check if the plant you buy meets your criteria and is foolproof for future use.

- Updates: There will be some updates which may not be required immediately. But in future the plant should be designed to accommodate any additional components or accessories.

Conclusion

Atlas Technologies provides solutions with respect to the concrete batching plants. We have machines to suit different customer’s requirements with proven design. To know more, contact Atlas Technologies Pvt. Ltd. .

Facts about bitumen tanks...

When we manufacture an asphalt plant, every component is built...

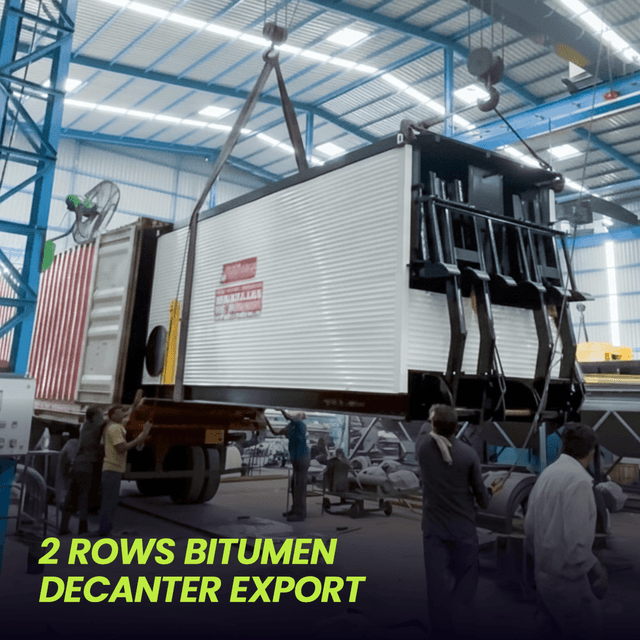

2 rows containerized bitumen decanter...

The export of a two row containerized bitumen decanter offers...

A Comprehensive Guide to Concrete...

Concrete is the main building material on which the reliability...

Understanding the asphalt mixing plant...

At Atlas Technologies Pvt. Ltd. we are committed...