Bitumen pressure distributor is one of the road construction machinery manufactured and developed especially for the purpose of coating and bitumen distribution. The process of uniformly distribution of liquid bitumen on the road surface is very important. The anatomy of bitumen pressure distributor is described in details in this blog. The specialty of this equipment is that it can spray controlled quantity of bitumen on the road and in the required manner. This helps to apply a uniform and required coat of bitumen on the surface without any wastage. Usually, we mount the equipment on a truck chassis which makes it easy to spray bitumen while the truck is moving. The anatomy of asphalt distributors consists of different parts laid out and explanation of the same. The job of the truck chassis will be to carry the machine and move it sluggishly so that invariant spraying of bitumen can be done. With the bitumen sprayer, emulsion spraying is also possible. Whenever there’s demand for emulsion spraying, this machine can perform. The main advantage of this machine being its easy to use design.

Atlas has taken acceptable care in developing a quality machine. Proper care has been taken in designing the flow channels and the tank structure in such a way that liquid bitumen flows fluently. The return lines aren’t parallel to the chassis. They are at an angle which makes sure that bitumen flows fluently without congesting the lines. The tank designed is round shaped which looks aesthetic and is painted in black which makes it look clean and camouflages bitumen spillage. The overall design is pleasing on the eyes without compromising on the mechanism of the machine. The core focus is to develop a machine which performs best under different conditions.

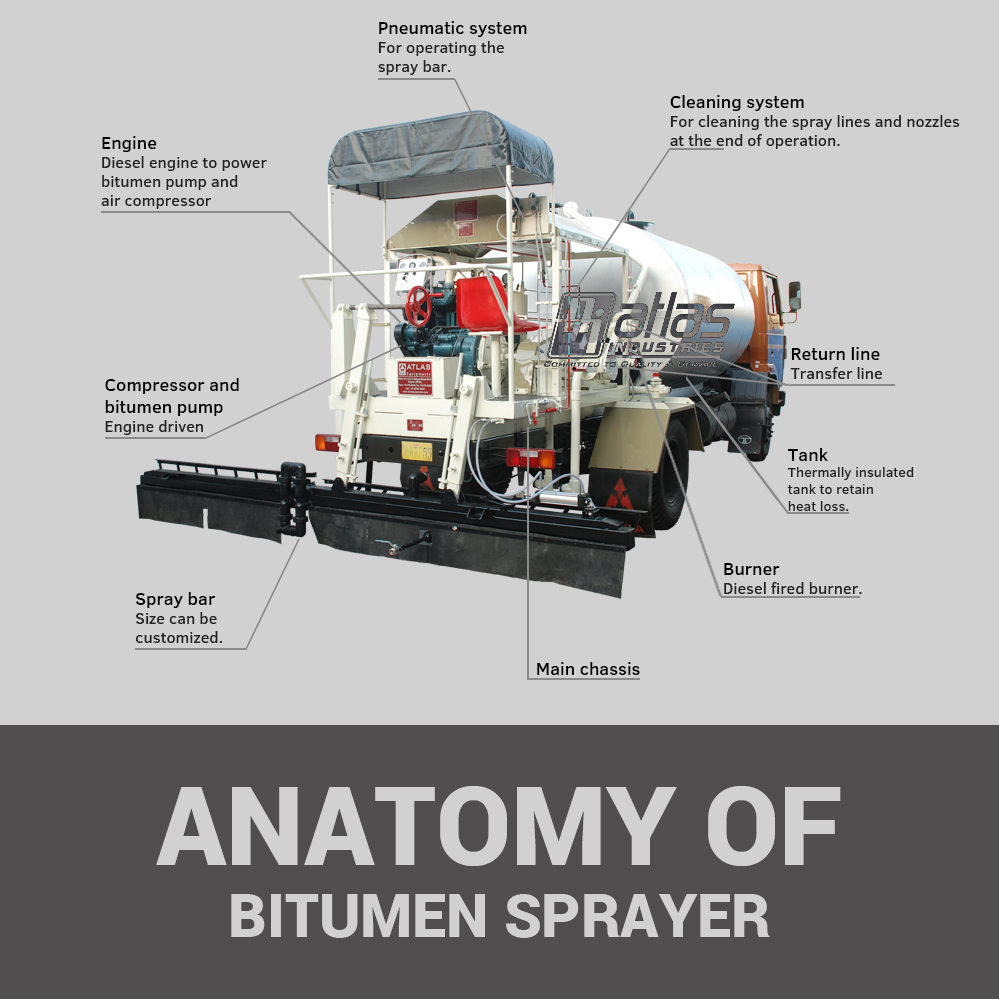

Anatomy of Bitumen Pressure Distributor

The anatomy of bitumen pressure distributor consists of its different parts. The main parts of bitumen pressure distributor / sprayer are main chassis, tank, burner, machine, bitumen pump, air compressor, spray bar, pneumatic system, cleaning system, transfer line and return line. Each of the element of bitumen sprayer works efficiently to give proper spraying efficiency.

MAIN CHASSIS

The main chassis is the base on which the entire equipment is build. Chassis of the sprayer is a combination of two channels which will hold the unit. The width of the sprayer chassis is customized. Customization is in the form of the distance between the two chassis bars. The factor impacting this is the vehicle on which the sprayer will be mounted. Depending on the chassis width of the vehicle, the machine chassis width can be customized so that the sprayer fits exactly on the vehicle.

TANK

The tank constructed is round shaped and is completely insulated from all the sides by 50 mm glass wool. This insulation of the tank on all the sides will help in keeping the contents of the tank hot for longer duration. Atlas is one bitumen pressure distributor manufacturer who offers the tanks with galvanized coating and with color applied on the tank.

BURNER

Burner is a simple high pressure oil burner equipped in the tank. It’s capacity is for acceptable heating of bitumen. Burner uses diesel energy to heat the contents. A lower hand held type burner is handed for heating the pipelines in case of any clogging. This helps to work in extreme cold conditions. A fuel tank of 100 liters for the burner is equipped with the distributor.

MACHINE

Machine is standard Kirloskar make of capacity 25 HP operating at 2000 rpm. Machine powers bitumen pump and air compressor.

BITUMEN PUMP AND AIR COMPRESSOR

Bitumen pump is connected to the machine by a heavy-duty clutch. The pump is of a high capacity and is gear type. Air compressor is double cylinder type powered by the machine by a V belt.

SPRAY BAR

Spray bar height adaptation is mechanical and there’s also heating facility available by rotation of pre-heated bitumen. Spray bar is of length 4.2 m allowing spraying of up to 4.5 meters. This setup can also be tailored to achieve spraying widths of over 6 meters. Additionally, an asphalt distributor is equipped with a hose pipe featuring a single nozzle for hand spraying of bitumen.

PNEUMATIC SYSTEM

Pneumatic system is for opening and closing of nozzles on the spray bar. The hand lever valves are handed near the machine operator’s seat.

CLEANING SYSTEM

Cleaning system using air and diesel is a standard with this machine. At the end of operation, all the lines can be cleaned from bitumen by use of air and diesel. This will make sure that the machine works trouble free the next day.

TRANSFER LINE AND RETURN LINE

Transfer line is for transfer of bitumen inside the tank. The bitumen pump can serve dual purposes, both for filling the tank and spraying. The return line is positioned and adjusted to regulate the pressure of the spray bar. Its angle ensures that bitumen doesn’t accumulate and cause blockages within the sprayer chassis.

Atlas is manufacturer and exporter of top-notch bitumen pressure distributors from India. We manufacture this equipment to suit customer’s requirement and fit their existing new or old truck chassis width. Contact us to know more.