The hot mix asphalt plant, also known as the hot mix plant, functions as a system that features a combination of multiple electrical and mechanical components that work together in sync. Now, through the combination and operational efficiency of the components.

It is possible to get the cold aggregates heated up and then mixed with the minerals and liquid bitumen in different proportions so that the asphalt mix is made according to the requirements of a project. This can be done by using a drum mixer or an asphalt batch plant. Do you know that these two differ to each other?

The hot mix asphalt plants can be either portable or stationary. The components used in the stationary plants are fixed. On the other hand, components used for the portable plants are on wheels, thus making it easier to move them from one point to another.

The hot mix asphalt plants are further segregated into two categories, namely continuous-type models and batch-type models. The continuous hot mix asphalt plants can generate asphalt mixture in a continuous operation, whereas the batch type plants make the hot mix asphalt in batches.

While working with the continuous mixing plants, ingredients get added into the machine, and dried and mixed in the drum. With the batching plants, the ingredients are first pre-weighed according to the required amounts and added into the pug mill mixer for creating the batch.

The two primary variants of asphalt plants used for the hot mix asphalt material are:

- The asphalt drum mix plants and

- Asphalt batch plants.

Batch Plants VS Drum Plants

The asphalt batch plants help in creating the hot mix asphalt material in fixed batches. Separate batches are made continuously for making hot mix asphalt.

The key advantages of using the asphalt batch plant units are discussed in detail below:

- These plants ensure the quality production of the hot mix asphalt.

- With these machines, users can get maximum flexibility.

- The control systems equipped with these machines are highly advanced and allow the users to work on multiple options.

- These machines allow the users to edit the batch sizes so that material designs can be mixed frequently.

- The pollution levels get better controlled with the asphalt batch plants than the drum mixers.

While it is true that the asphalt batch plants come with the advantages described above, the drum mixers are still commonly used in developing countries.

Asphalt drum mix plants can produce HMA regularly in a straight and continuous process. Hence, it makes them beneficial for different types of small to medium-sized construction projects. However, it is imperative to note that the final product quality is not as good as the asphalt batch plant.

Advantages of the drum mixers

Here are the benefits of working with the continuous drum mixers:

- Initial costs for operating the continuous drum mixers are low when compared to the asphalt batch plants.

- With the drum mixers, the production process will be continuous, which ensures uninterrupted production.

- The area needed to set up the continuous drum mixer is less than required for an asphalt batch plant.

- Upgrading to a higher capacity and performance machine without much increase in price is possible.

- It is easy to operate and maintain this machine.

Even though the functioning of these plants is different, both of them have the main task of producing hot mix asphalt according to the requirement.

The counter-flow asphalt plant also works as a widely used continuous plant for road construction and the production of hot mix asphalt. However, it features a different type of technology when compared to traditional models of drum plants. In the counter flow plant, the flow of aggregate is opposite to the flame direction. Dust suction is performed when the aggregates get into the drum. The counterflow plants often have a single drum to manage the drying and mixing. Alternatively, they can also have two drums that perform the drying and mixing separately. It can have a drum for conducting the heating and another mixer for mixing.

Typically, the drum plants used are smaller in size than the ones used in asphalt batch plants. They also require less energy and less space and can be operated with little effort. Components present in these drum asphalt plants are lesser, and a lot easier for the users to transport the units and ship them.

These are the things that we intend to discuss in this blog below:

- Components and operations that are common to both drum mixers and asphalt batch plants.

- Operations of the parallel flow asphalt batch mixing plants.

- Process of the counterflow asphalt mixers.

- Working on the asphalt batch mixing plants.

Some operations are common to drum mixers and asphalt batch plants, and many of their components are similar. These are listed below:

- Component: Aggregate feeder

Operation: Storage and feeding of the cold aggregates - Component: Drum and burner

Operation: Drying and mixing in parallel flow type. Only drying of the aggregates in the batch-type unit - Component: Fuel tank for dryer burner

Operation: Storage and supplying the fuel to the burner. - Component: Primary scalping screen and charging conveyor

Operation: Removing oversized materials before the stage where the aggregates get into the drum. - Component: Primary and secondary pollution control units

Operation: They help in the collection of fine and heavy particles. - Component: Asphalt tanks

Operation: Heating and storage of bitumen. - Component: Filler bins

Operation: Transferring and storage of the filler material. - Component: RAP feeder

Operation: It helps in the feeding of the recycled material - Component: Control panel

Operation: It helps in controlling the whole plant. - Component: Storage silo

Operation: It helps in the storage of the hot mix asphalt before dispatch.

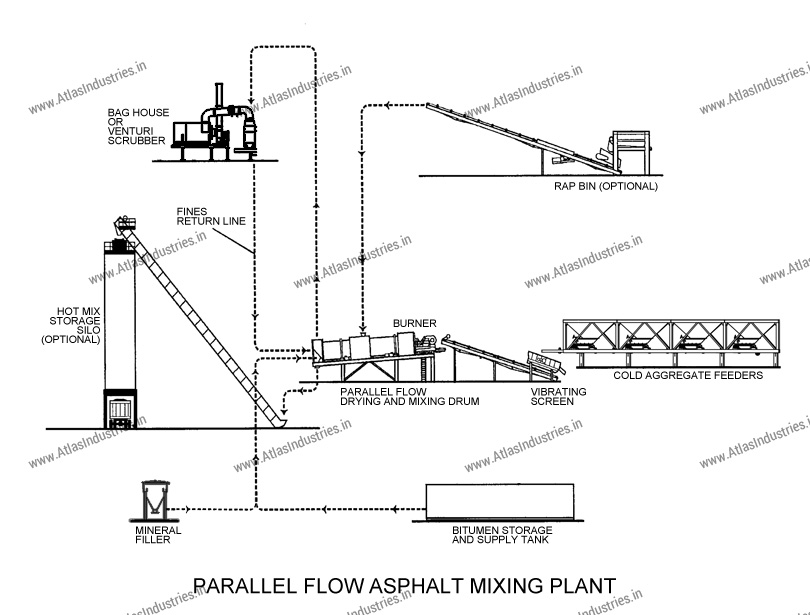

Operation Of The Parallel Flow Asphalt Mix Plants

The parallel flow type models of the asphalt mixing plants operate continuously, wherein the ingredients are moved into cold feed bins according to specific proportions. The feeder bins store the cold aggregates within separate bins so that they can be transferred to the system’s drying drum. The principal difference between this specific process and bath plants only starts here.

There’s one single drum that can heat and mix the asphalt in one single drum or chamber. The aggregates are put into the burner end of the drum. The flow of the aggregates is parallel to the burner flame, and hence it is called a parallel flow asphalt mix plant. Before the aggregates are placed into the drum, they first pass through the primary scalping screen. It is here all oversized aggregates get removed.

Once the cold aggregates get into the drum, they get exposed to hot flames, which treat them to hot flame and later combined with hot bitumen and the other additives. The aggregates move steadily towards the opposite end of this drum with its rotation. The aggregates combine with liquid bitumen at a later stage. The liquid bitumen flows through a pump managed with a sturdy variable speed drive.

It means that the flow of the aggregates can determine the addition of the minerals and bitumen inside the drum. When the flow of aggregates is greater, a message is sent by the control panel to the bitumen drive so that bitumen is in definite proportions and measures to the aggregates. If the flow of aggregates drops, the inflow of bitumen inside the drum gets decreased by the control panel. RAP and minerals are added inside the drum at a point where the temperature is typically much lower. The introduction of these minerals and the recycled asphalt is well-controlled by the variable speed drive similar to the bitumen.

Exhaust gases get sucked in the direction of the discharge side of the drum. They are also first treated by the primary and the secondary dust collector. The primary dust collector often described as a cyclone device, will trap the heavy dust particles to avert them from entering the secondary dust collector. The secondary dust collector system is generally a venture scrubber-type wet dust collector and/or a baghouse filter that helps settle down the lighter particles from escaping. The wet dust collectors can work with the water jets for trapping and treating them to the cyclonic effect for settling the dust. No water is needed to clean the bag filters. The filters clean the dust by simply trapping it inside the bags constructed of a distinctive material meant for this purpose.

The mixed material is dispatched from the lower side of the drum. It is then transferred to the truck or the storage silo. In case it is moved to the hot mix silo, the material can be moved into the truck.

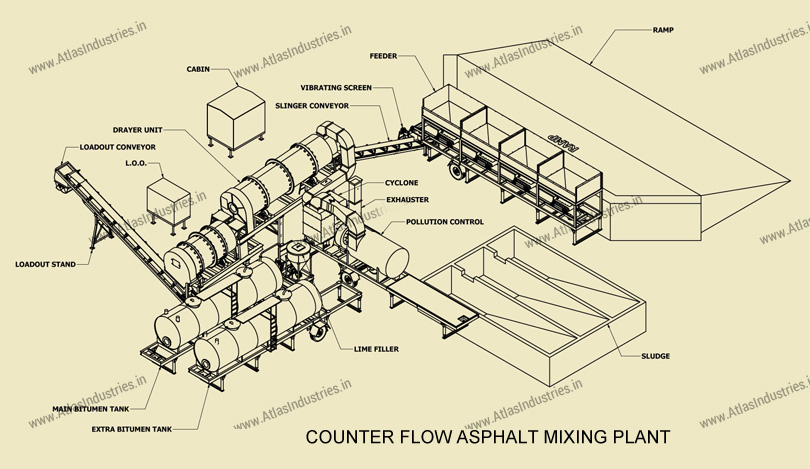

Process Of The Counterflow Asphalt Mixer:

The process involved with the counter-flow asphalt plant is very similar to a parallel flow plant. It is a continuous process. In the counterflow asphalt plant, the entry and the number of minerals and bitumen are managed by the flow of aggregates similar to the parallel flow plant.

The main difference lies in the fact that the flow of aggregates is different in terms of the burner flame’s position as it is the opposite. It is for this reason that the system is called a counterflow asphalt plant. The flow of the exhaust gases happens from a point where the aggregates get into the drum. The RAP, minerals, and bitumen are added from behind the system’s burner flame. Such addition of the RAP, bitumen, and minerals can take place in the same drum. It can be added in another separate mixer or drum. In this way, the bitumen, minerals, and RAP are prevented from the hot flames.

The addition of RAP, liquid bitumen, and minerals is managed with the help of a variable speed drive. It is synchronized effectively with the flow of aggregates in a way similar to the parallel flow mixers.

In these machines, only one single drum finds its usage. The flowing of the aggregates and the burner flame occur in opposite directions. The addition of the RAP and the liquid bitumen happens just behind the burner flame.

Two separate chambers exist at this point. There is a counterflow drum intended to dry the virgin aggregates. The other one is a pug mill-type mix unit that helps in mixing the hot aggregates with the liquid bitumen and RAP.

Here we can find two drums placed one above another. There is the drum that receives the virgin aggregates. It is well-equipped with a burner on another side. Only the drying of the aggregates happens in this drum. Over this drum is yet another drum ensuring entry of the RAP and liquid bitumen. The aggregates get moved after heating to this outer drum via the openings in its inner drum.

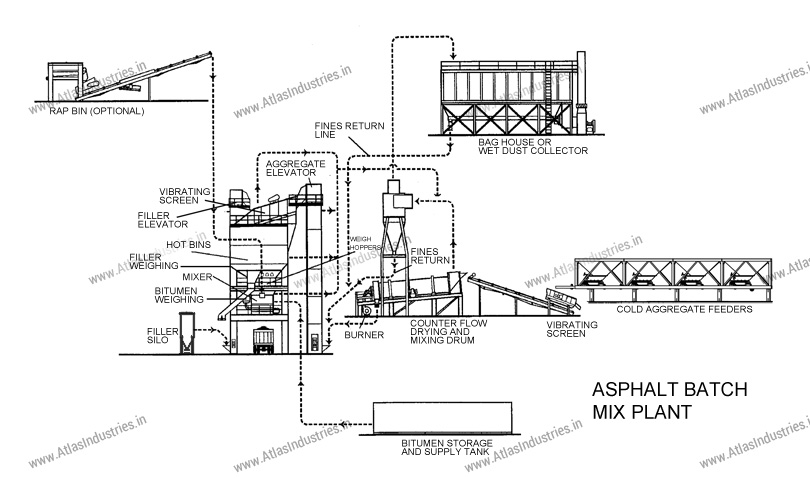

Working Of The Asphalt Batch Mix Plants:

Advanced technology is used for making the asphalt batch mixing plants and generating the best quality HMA. The process involves feeding the cold aggregates into the proper aggregate feeder bins. Once done, the material is metered individually from the hoppers and then moved to the drying drum. They need to pass via the primary scalping screen so that oversized materials can be eliminated or removed. The cold aggregates get moved by a conveyor into a drying drum.

This drum here is a counter flow type unit. It uses the drum rotation technique to move the dry aggregates from one end of the system to the burner. In the course of this movement, the aggregates have to be dried and moved to an elevator, which is fully covered. The elevator moves the aggregates to the upper end of the tower unit. It is a point where the multi-seck vibrating screens are positioned.

Dust collection takes place at the point of entry of the dry aggregates. The treatment uses a primary and a secondary dust collector. The primary dust collector has a cyclone shape. The secondary dust collector is either a baghouse or a wet scrubber.

The screens placed horizontally are of diverse sieve sizes. It depends on the type of mixed material and its requirement. The aggregates are passed through this vibrating screen. The aggregate particles are separated then placed in separate bins just under the vibrating screen. Such a separation is carried out according to the size of aggregates. The screen provides a feature for removing oversized and overflowing materials. In some asphalt batch plants, there is a separate bin that can store the RAP material. These aggregates are then stored separately in the bins. The bins open according to the batch for which it is set.

The quantity or amount of each type and size of aggregates are well-managed as per the requirement. Simultaneously, the bitumen stored in the bitumen tanks flows from tanks sited underneath using an asphalt pump to a bucket close to the mixer. The bucket will weigh the bitumen before it pumps the material into the mixer. Before the bitumen gets into the mixer, the RAP and the hot aggregates are placed into the mixing unit. The material to put into the mixing depends on the desired ratio. Users can also decide on the mixing time of the twin-shaft mixer.

Once the mixing process is over, the HMA gets discharged into the storage silo. Alternatively, it is transferred into the waiting trucks below to move them to the main job sites.

Since you intend to make a long-term investment, you should consider your primary requirements to choose your product. Many manufacturers design and produce drum and asphalt batch plants for sale. Before buying equipment like this, you should check all the models and the asphalt plant parts. It will help you to make sure that the products suit your needs.

You should also see that the product you are getting is easy to use, transport, maintain, and affordable. By choosing the best quality asphalt batch plant or drum mix plant, you can be in a position to earn a sufficient amount of financial returns. Atlas Technologies Pvt. Ltd have been offering cutting-edge asphalt batch plants and drum mix plants to our buyers for a long time now, and we can meet your specific requirements. Contact us now to get more details on the same.

More Resources: