India is a large market for construction equipment, including many asphalt plant manufacturers. However, only a few make batch-type asphalt plants, and even fewer are successful. Atlas Technologies is a trusted manufacturer in India and has been successfully offering batch plants to Indian customers since February 2014.

When you visit an asphalt plant, you’ll hear the machines, smell the hot bitumen, and see tall silos holding aggregates. All these things would give you a good experience. Arriving at the asphalt plant site, the first thing that might impact you is its sheer scale. Massive piles of gravel, sand, and crushed stone are neatly organized around the site. These aggregates are essential components of asphalt.

The plant’s layout was methodical, designed to streamline the production process from raw material intake to the final product ready for transportation. It’s been almost 9 years since we installed our first asphalt plant. This 80 tph machine with a wet dust collector was set up near Ankleshwar, Gujarat. In the early 45 days of plant installation at the site, we have gone through many problems. These problems were fixed, and the machine has been running smoothly since.

Perks of Asphalt Plant Installation at Site

Below are the perks of asphalt plant installation from the customer’s and company’s point of view.

From the Customer’s Point of View

- The plant has produced something around 100,000 tons of hot-mix asphalt.

- The best thing is that the customers are satisfied with their choice.

- The customer had the choice between a used Apollo plant and our new plant, which cost about the same.

- They took a risk by choosing our new machine, and they haven’t regretted it. At the time, the customer had looked at other suppliers and even saw a half-finished machine at our factory.

- This was their first batch mix plant, so they wanted to make sure they made the right choice. The setup was basic, with two direct heating bitumen tanks, a wet dust collector, and our PLC control panel.

From the Company’s Point of View

- In just 16 months since we built and installed our first plant, we’ve received orders for 12 machines, with most already installed across India.

- Three of these machines have produced over 100,000 tons of mixed asphalt without major breakdowns or needing many spare parts. It is a big achievement for a company with a new product.

- By the time of writing this post in 2024 August, we have successfully sold and installed over 210 asphalt mixing plants. Many of them have been installed outside India and are working successfully.

- We are the only India-based manufacturer to have installed 260 tph asphalt batch mix plants that are delivering to their 100% capacity without any issues.

- Many critical job sites in India and outside India are using our asphalt mixing plants.

- Our global installations (of all our products) have expanded to 48 countries and counting—data as of August 2024.

This post is about the fourth machine we manufactured and sold to an old customer from Punjab, India. The customer, a new road contractor in 2006, used our portable drum asphalt mixing plant that same year. Their company grew quickly, and by 2014, they wanted to buy a batch mix plant.

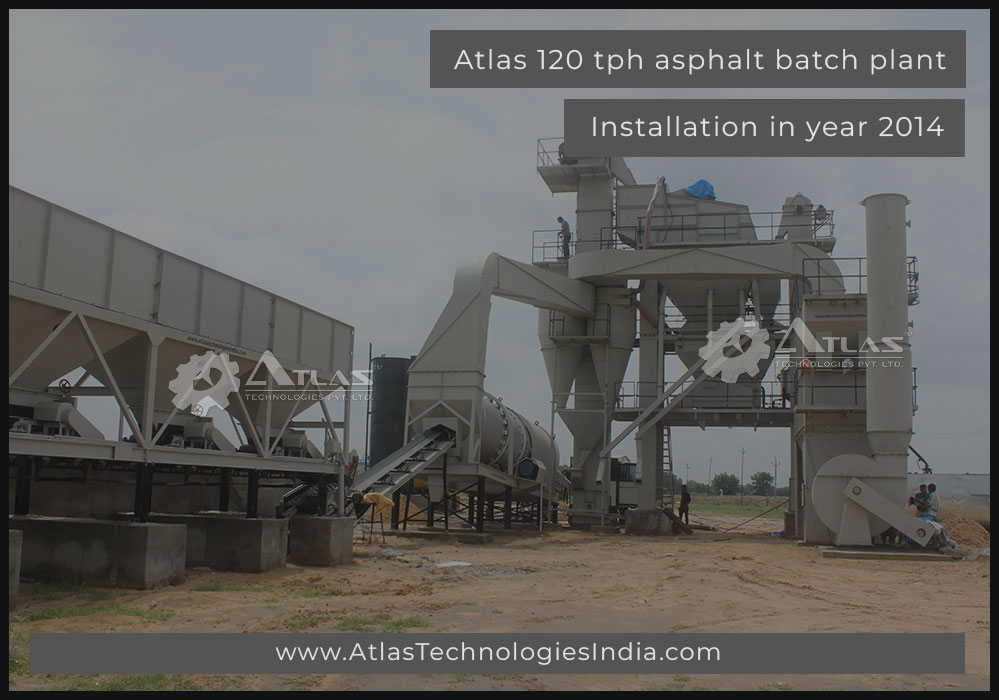

Our first drum mix plant’s proven design and high quality showed the customer that we were a serious, reliable company. When they were ready to make a significant investment, they knew we had equipment running successfully in India. After meeting to understand the product and specifications, they chose a 120 tph plant with two bitumen tanks, a bag filter, and a PLC control panel. The order was placed, and the machine was ready on schedule. However, the project was slightly delayed, and the customer received the machine a bit later.

We visited the site for a few days to help the customer start and calibrate the equipment. The mix design had a high dust percentage, around 47%, so we adjusted the pulleys for optimal bag filter performance. After a few days of use, the bag filter started getting clogged. There were three main reasons: high dust with moisture, high moisture in the aggregates, and unclean fuel that produced sulfur when burned. The bag filter struggled to remove impurities and moisture, which caused the bags to spoil faster.

After cleaning the bag filter, we conducted a successful trial that satisfied the customer. They were very happy. Four of our technicians stayed for another week to help run the machine and assist if anything went wrong.

The customer’s outstanding hospitality made our team feel at ease, so they stayed on-site for a few more days without any worries. The customer ensured our technicians had everything they needed, including top-quality food and beverages.

Atlas Technologies always aims to forge strong relationships with customers after selling equipment. This way, customers remember us for our quality products, services, and, most importantly, our honesty in our relationships. Contact us to design your next asphalt mixing plant from Atlas Technologies Pvt. Ltd.

More Resources: