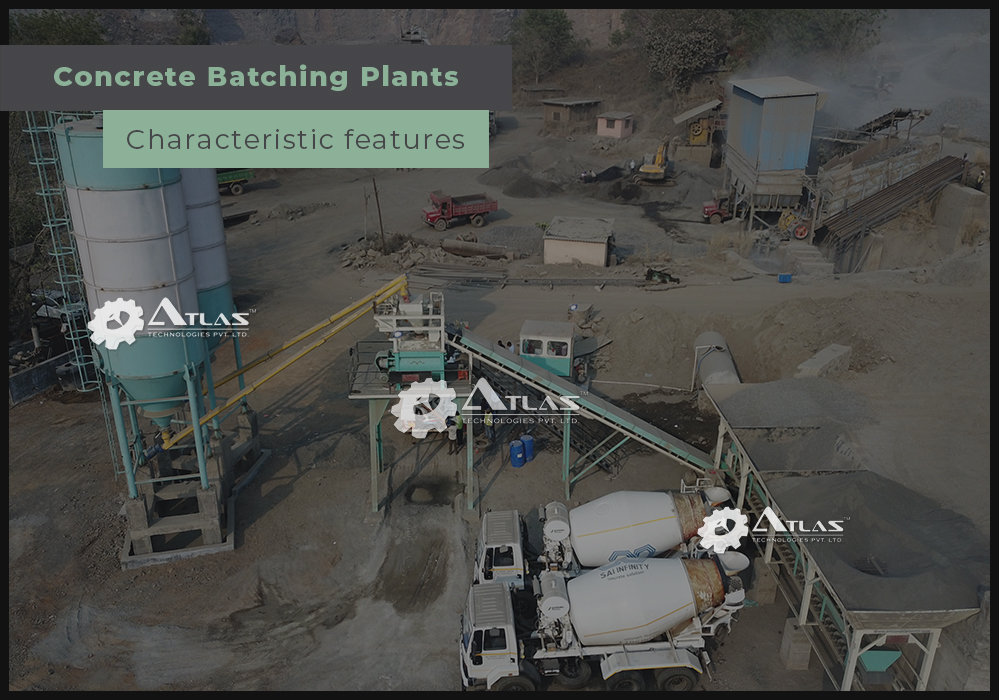

Modern contractors have in recent times grown heavily reliant on the concrete batching plant. There is hardly any construction work today that could be accomplished soundly without the use of these plants. That has made concrete batching plants indispensable to construction projects.

As critical as concrete batching plants are, good quality concrete is very essential. Without exact concrete mix recipe it is not possible to achieve the level of construction that we are doing today. The specific purpose of a concrete batching plant is to provide us with exact quality of concrete required for specific projects.

With good quality concrete, a lot can be achieved in construction jobs. There are jobs where precision and timeliness are vital. For such demanding projects, producing high-quality concrete in required amounts becomes tricky. That’s where good quality construction equipment come in handy.

Read Also: How to work with concrete and make money

With the right set of equipment, both quantitative and qualitative goals are achievable and in any given timeframe, no matter how short duration it might be. Thankfully, there is a whole arsenal of tools and equipment accessible in the market that can help contractors meet their goals easily.

Concrete batching plants make it possible to produce concrete in big batches. This helps wrap up projects within deadlines. To top that, these machines deliver precise results. With a very simple load cell based mechanism, these machines deliver surprisingly precise results.

The load cells form the weighing mechanism of the systems. With it, every element can be individually weighed with accuracy. The plants also have integrated material transfer systems the job of which is to move all units to the mixing center. At the mixer, all units are combined and finally poured out within the estimated time.

Concrete Batching Plant Five Major Parts:

- Aggregate storage and feeding system

- Water storage and feeding system

- Cement storage and feeding system

- Individual weighing units

- Material conveying systems (belts, screw conveyors, etc.)

- Mixing center

- And control panel.

There are other sundry optional components that vary from model to model. Concrete is produced in these plants through the combination of cement and sand with water. Additives are introduced to the mixture to create the final concrete.

With the increased availability of concrete batch plants in the market, the speed and quality of civil construction jobs have gone up by significant measures. Availability of quality machines supported the growth.

- The inline concrete batching plants manufactured by Atlas are made of high-quality steel and using the best quality components available in the market.

- These are designed to be transported in containers.

- They are very easy to install and use.

- The mixing performance of Atlas concrete plants is pretty high.

- The mixers in the machines are outfitted with plates that are highly resistant to friction and tension.

- The planetary gear boxes of the shafts are heavy-duty.

- The mixing core of the plants ensure uniform mixing in no time.

- Control panel is designed for ease of usage.

The machines also come with their individual set of accessories, namely screw conveyors, pneumatic sensors, load cells, air compressors, etc. All materials and components used in the making of the machines are sourced from trusted suppliers and they all come with the assurance of prolonged and reliable functioning. The load cells integrated in the systems ensure all items introduced in the mix are weighed correctly.

As a manufacturer, Atlas understands the challenges of maintenance and so they have made their batching plants maintenance-free. Come explore with us the possibilities that we have to help make your concreating easy.