Every contractor that works on road construction projects uses WMM plants since they are a piece of essential equipment for the road-making process. Also referred to as the soil stabilization plans, such machines are fundamental for producing materials that can help stabilize the soil before putting the hot mix asphalt in it.

In most instances, sand and aggregates are blended with water along with some cement. The overall percentage of the cement remains between 3% and 5%. However, it can vary as per client requirements. Even though a small percentage of cement is mixed, it serves as a primary binding material within the mixture. The blended materials give sufficient strength and resilience to the floor.

The wet mix plants manufactured in India come equipped with a primary vibrating screen, aggregate feeders, a charging conveyor fitted with the load cell to weigh the aggregates, a load-out conveyor, a pug mill mixer, and storage silos. These plants have cement silos. It is applied when adding more cement directly to the mixing unit.

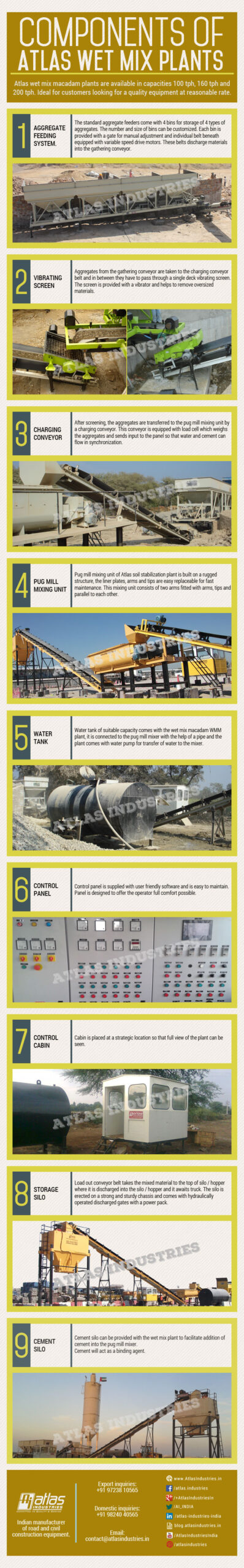

COMPONENTS OF THE WMM PLANT

WMM plants designed and produced by Atlas can sustain severe working conditions. The various components associated with the wet mix plants are known for their heavy designs. For instance, pug mill mixers fitted with wet mix plants are indeed strong. Hence, they can manage heavy loads very conveniently. They can also deliver smooth performance for a long time. The design of the pug mill mixers is simple, making them low in maintenance. They have unslotted shafts and rest on six pedestals. The plants provide excellent performance. You get to benefit from superior mixing and top-notch service support from the expert technicians at Atlas. So, you can get the most output from these machines.

Here is a look at the core components of the WMM plants offered by Atlas.

- Aggregate feeding system

- Vibrating screen

- Charging conveyor

- Mixing unit

- Water tank

- Control cabin and panel

- Storage silo

- Cement addition

- Aggregate feeding system: The aggregate feeding systems equipped with the WMM plants have a set of standard bins with four feeders, and each of these bins has individual gates to ensure the controlled flow of the aggregates. The sizes and the numbers of the bins can be conveniently customized. Each of these bins comes fitted with a gate to ensure manual adjustment. They have individual belts driven by speed-drive motors with a variable speed. A bigger conveyor for gathering is placed below each of the bins. The conveyor belts can discharge the materials in the gathering conveyors.

- Vibrating screen: The aggregates obtained from gathering conveyors are moved to the plant’s charging conveyor belt. As they pass through the two belts, the aggregates pass through the single-deck vibrating screen. A screen comes fitted with a vibrator that prevents the oversized material from reaching the mixer.

- Charging conveyor: The charging conveyor helps move the aggregates to the pug mill mix unit. The conveyor is equipped with a high-capacity load cell to weigh the aggregates. Once the weighing is carried out, it sends a signal to the control panel. The signal can help the panel effectively synchronize the addition of water and cement into the plant’s mixing unit.

- Mixing unit: The mixing unit is put on a highly rugged structure, and it works as a continuously functioning pug mill mixer. The liner plates, tips, and arms that come with the system are replaceable. The sturdy mixer system has a simple and effective design and is easy to maintain. The mixing unit comes with two shafts. The shafts have arms fitted on them, and they stand parallel to each other.

- Water tank: A water tank of requisite capacity comes equipped with the plants. The water tank is attached to the pug mill mixer through a pipe. The plant is fitted with a water pump to transfer water to the mixer. The flow of water is controlled depending on the specific input from the load cell.

- Control cabin and panel: The control cabin is where the control panel is. The control panel is a PLC type or microprocessor depending on which specific model gets chosen by customers. It also has easy-to-use software, making it convenient for the users to work with the control cabin.

- Storage silo: Storage silos of suitable sizes are available. These silos can assist with material storage before being discharged into the trucks. The silo is set up on a rather heavy structure using hydraulically operated gates to provide an open-close mechanism.

- Cement addition: Adding cement is made possible with the hopper or the cement silo. A screw conveyor can be used to add cement to the mixing unit.

How is a wet mix made?

Stone aggregates, water, and cement are used to create a wet mix of macadam. A granular subbase is laid by combining all of these components in the desired proportions. A wet mix macadam plant is used to make wet mix material in precise proportion and in high quantity.

Why do we use WMM?

The wet mix macadam strategy incorporates the spreading of well-blended material arranged for a sub-base. Aggregates, water, and cement are all included in this.

More Resources: