Atlas offers top-of-the-line portable asphalt plants for the Algerian market. In December 2014, Atlas confirmed the order for 90 tph to 120 tph portable asphalt plants for Algeria. The order was placed by a road contractor company from Algeria, and they were searching for high-quality and high-performance asphalt drum plant equipment that provide them with a stellar performance. Their in-depth knowledge of asphalt drum plants made it possible to know what they were looking to buy.

We are thrilled to share an exciting milestone in our journey of bolstering global infrastructure development. Today, we proudly unveil the latest addition to our line of cutting-edge asphalt plants—a state-of-the-art marvel that we recently exported to Algeria, a nation with a growing appetite for advanced infrastructure solutions.

The Algerian company already got in touch with multiple Indian manufacturers of high-end road construction equipment to make their purchase. While conversing with the team at Atlas, the customer felt comfortable and had a sense of trust. Atlas Technologies provided contact details and references of our old and existing customers from Morocco to know more about the quality of services we have to offer. The Moroccan client we have has been using our top-quality hot mix asphalt plants since 2010. As the Algerian customer interacted with the Morocco-based customer, he was satisfied with the input and feedback he got.

Asphalt Drum Mixing Plants in Algeria

From the beginning, we consider the needs of the customers we serve and if needed, we customize our asphalt drum mixing plants. Our Algerian customer had in-depth knowledge of the asphalt drum mix machine, and they precisely what he was looking to buy. As we decided on the various technical details of the machines, we provided them with a production time so that they get their asphalt drum mixer plants.

We promised them a specific delivery time of 45 days as we also had other orders to handle. Even though this made the customer a bit uneasy as he wanted the asphalt mixing plants as quickly as possible, we explained to the Algerian client that the scope of their order was big, and we had our hands full with other orders too. So, it will take a bit longer for us to handle the manufacturing process. We assured the Algerian customer that we are one of the best exporters of these machines and do not simply take the order and not deliver the product on time. Listening to this, the customer was convinced and placed the order with us.

Also Read: Asphalt Batch Plant Features And Components

The asphalt plant we provided our Algerian customer came with crucial components like below:

• Four bin aggregate feeders

• Vibrating screen and charging conveyor

• Drag slat conveyor for load out

• Drying and mixing unit

• Two bitumen tanks with a combined bitumen storage of about 50 tonnes

• Mineral filler unit

• Fuel tank for the dryer burner and

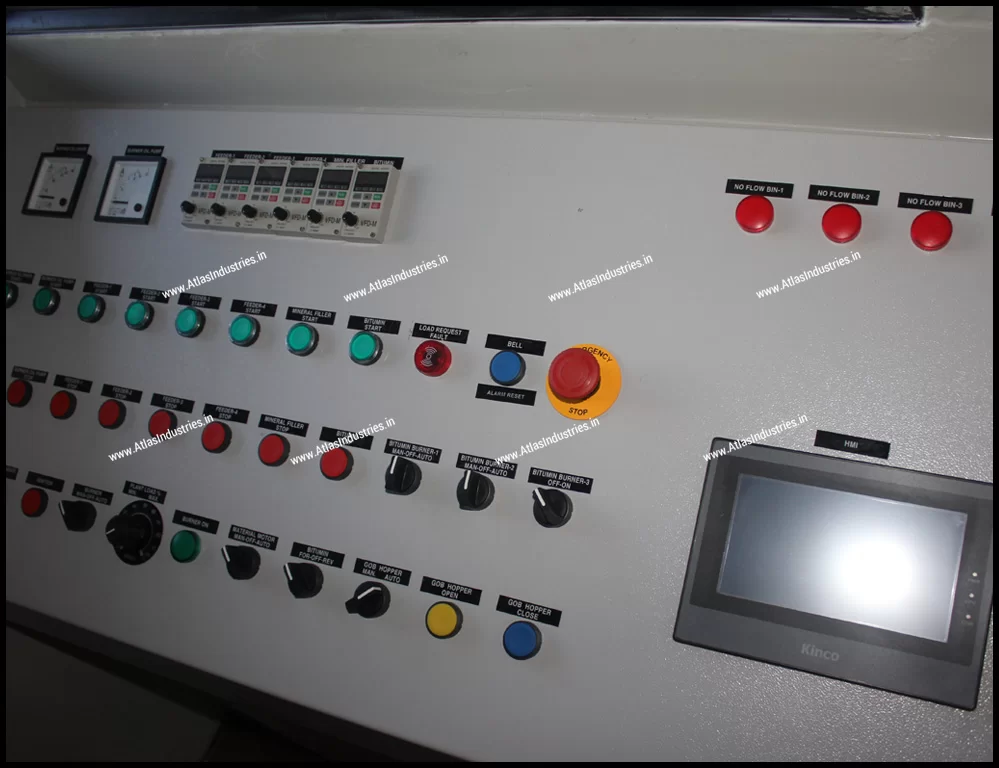

• PLC touchscreen type control panel housed within the control cabin.

To manage the pollution control goals of our customers, we placed a wet and dry dust collector unit inside the system as a standard package. We also provided some fast-moving spare parts for the Asphalt Plants. All of these were offered to the Algerian customer as a standard package.

Contact us to know more about various solutions that we have regarding your requirement of quality hot mix asphalt.