It is now crucial that contractors seek a movable asphalt plant given that there are many projects contractors handle at once and it is becoming common practice to tender for more than one project at a time. These contractors are nimble, for they are able to handle many projects at the same time as the need for a solution that is flexible and promotes project efficiency. Mobile asphalt plant serves an important purpose in cases where dedication of a specific piece of equipment for every project is not feasible.

Key Advantages Over Stationary Counterparts

In such places as Zimbabwe, Oman, Botswana, Nigeria, Philippines, Algeria, Myanmar Ivory Coast, etc., Atlas Technologies Pvt. Ltd. have incorporated atlas mini-asphalt plants that are affordable. The mobile plants range from 60 tph to 150 tph and they are preferable than their stationary versions. The benefits of such an arrangement comprise maintaining constant output level, identical heat mix quality, same size, zero or minimum base / foundation requirement, speedy installation, ease of disassembling and re-erecting, prewired facility and transportation convenience.

Read Also: 40-60 TPH Mobile Asphalt Drum Mix Plant for Philippines

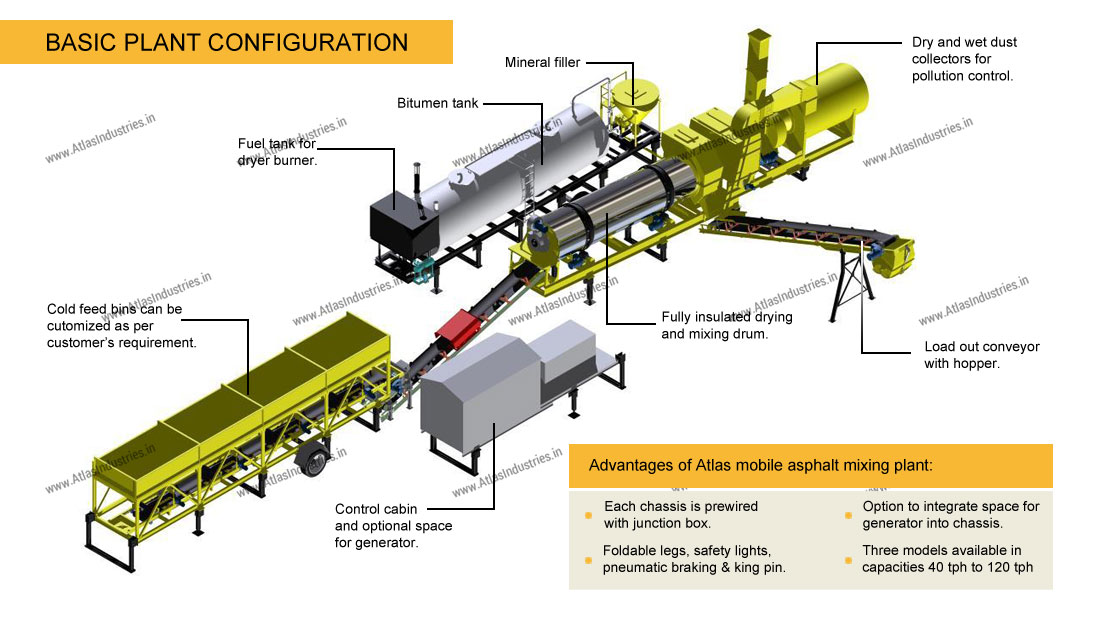

Unchanged Layout with Enhanced Flexibility -Mobile asphalt drum plant

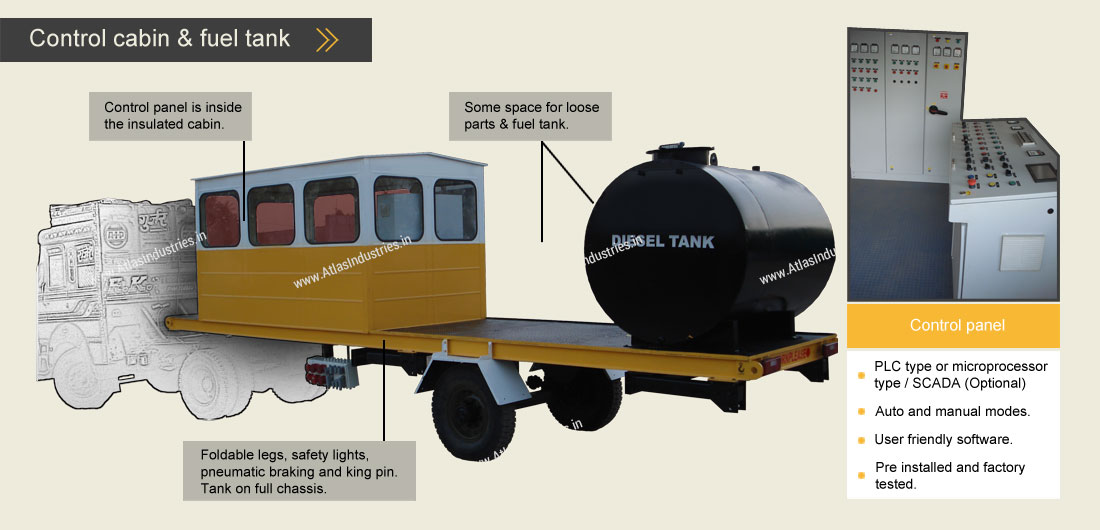

Like a Stationary Asphalt Mix Plant, the layout of the Mobile Asphalt Mix Plant is similar. However, the inline feeding units can be adjusted in numbers with vibrating screen, a charging conveyor, and a drying drum operating in line. Wet dust pollutant control device shares the same chassis with drying and mixing drum of the hot mix plant. On the other hand, the bitumen storage and transfer tanks, fuel tank for the dryer burner, and mineral filler unit can be on the same or separate chassis depending on the choice of the bitumen tank size. The chassis provides room for the control cabin together with the optional accommodations for a generator.

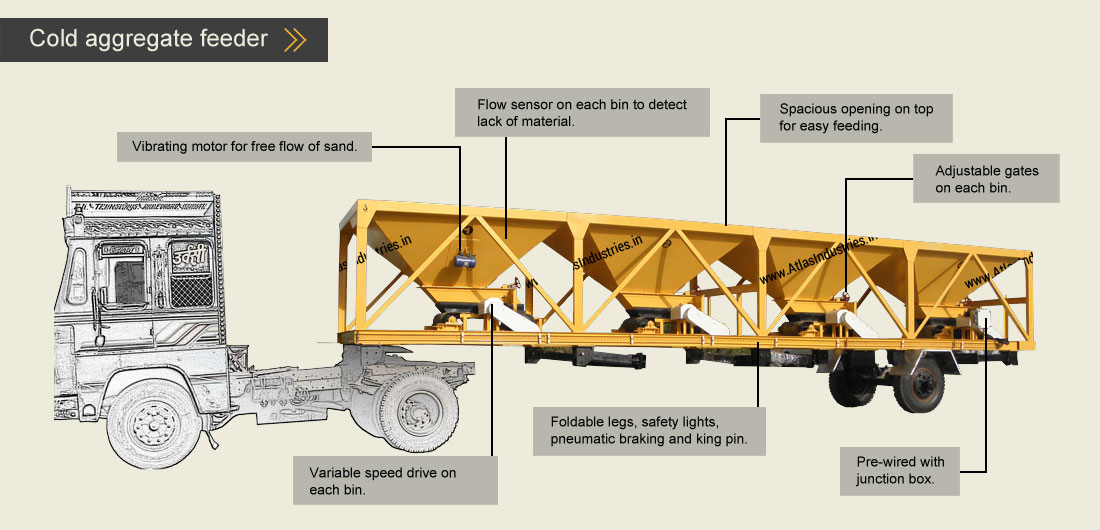

Optimised Cold Aggregate Feeder Design

Cold aggregate feeder usually has four bins; however, it can be customised. There are manual feeder gates in each bin as well as variable speed drive motors. There is also a separate sand bin with a vibrating mechanism that allows free movement. The supply of materials in every bin activates flow sensors that send an alarm message into the panel if there is lack of material. The feeding unit chassis includes collapsible legs, safety lights, air brake valve, and kingpin for ease of connection with a truck.

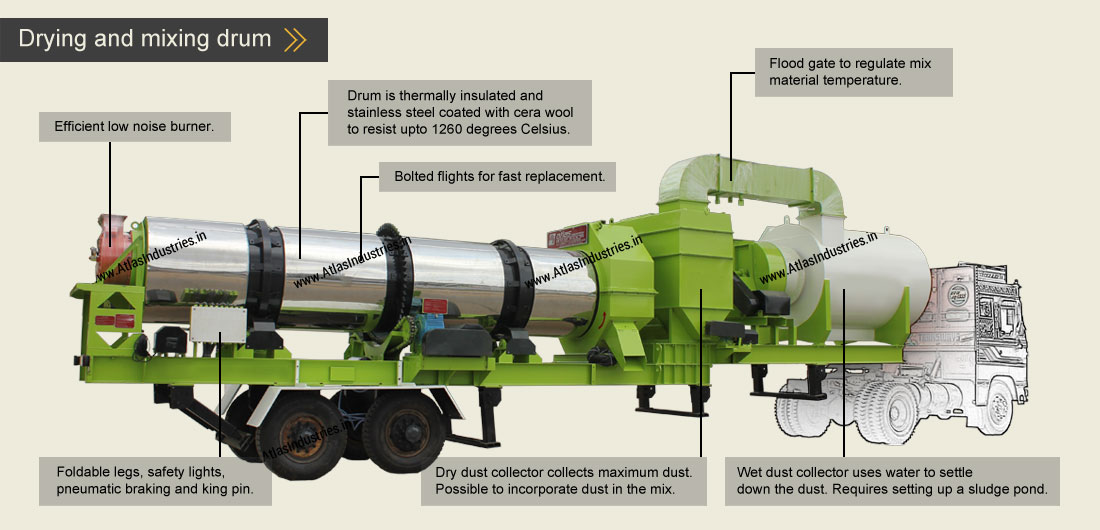

Mobile Drying and Mixing Drum

Chassis accommodates mobile drying and mixing drum combined with wet venturi type dust collector. Burner which is efficient, suitable for diesel and is optimised for saving on fuel. This also involves thermal insulation on the drum by applying cera wool and metallic stainless steel outer coverings for energy saving at the factory. Indeed, Atlas thinks about the customer and its return on investment.

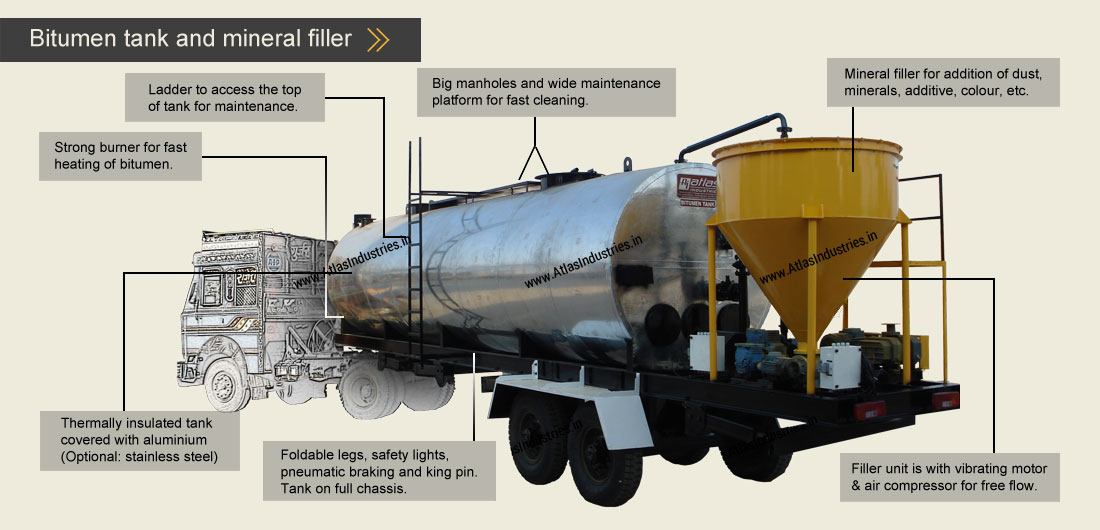

The Versatile Design of Mineral Filler for Bitumen Tank

Considering the tank’s capacity, it can accommodate the bitumen tank, mineral filler, along with its full insulation, and fuel-efficient burner. The tank is lifted separately, since a separate chassis ensures its transportation.

Control Cabin: Efficiency in Operation

For large bitumen tanks, the control cabin is normally mounted in a separate chassis that could also incorporate additional components such as the fuel tank or filler unit. It has a full insulation, PLC type control panel that includes a touchscreen panel and user-end friendly software. It is a fully-fledged portable plant which is mobile, convenient and low-maintenance.

Choosing Between Stationary and Mobile

Finally, the choice between the stationary or the mobile plant is subjective depending on an individual’s preference or the stipulations of the project. Mobile Asphalt Plant is an appropriate flexible option to efficiently manage the projects. It has its own advantages and features that adds to the value of any project. Contact us with your requirement to know more.