Innovation knows no boundaries, and the construction industry in India is a testament to this fact. As technology advances and new solutions emerge, traditional construction practices are being revolutionized, leading to increased efficiency and cost savings. One such groundbreaking development is the installation of a portable concrete mixer at an industrial park in India. We have been fortunate enough to work with different clients from different industrial sectors.

Working with different clients has given us a proper understanding of their needs and aspirations. Here is one such experience that has been narrated here. This is a client from Gujarat that we had worked with. We are happy to match their standards.

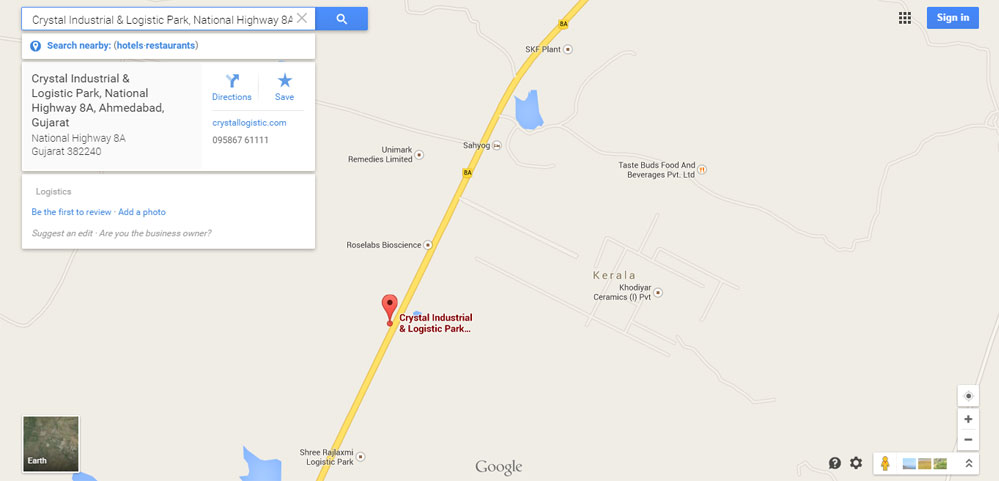

The time taken to travel to the portable concrete plant from Ahmedabad was not much since it is located nearby. The plant that we at Atlas sold to our customers was installed and set up at a nearby industrial park located on the Ahmadabad-Rajkot highway.

The distance between the industrial park and Ahmedabad, the nearest, is around 42 kilometers (Bhayla village). The area has medium traffic. Hence, anyone can reach Crystal Industrial and Logistics Park within about 45 to 60 minutes. The machine we designed and manufactured helps our client make concrete flooring and concrete roads at this industrial park.

I spoke and interacted with the customer one day before. At this time, I was informed that I could visit the place to take some videos and pictures of the plant. The customer informed me that the equipment will be operational at about 9 am and will run till about 1 pm. It means that I can reach the place at any time.

To reach Crystal Industrial and Logistics Park, I left Ahmedabad at around 7:30 am. I considered early morning to be the best time to start my journey, as I wanted to explore the plant and take some great snaps without the sun directly above my head. Due to the traffic, I finally reached the park at about 8:15 am.

Upon reaching the plant, I was cordially welcomed by a kind man. He took the time to guide me through the area. I was delighted to get acquainted with a nice and humble human being who treated me with a lot of respect. I was pleased to see him, as he treated me well, even if his work required him to sit all day in a rather dusty environment.

During the early hours, the operator focused on laying bricks right under the control cabin of this portable concrete plant. To protect the cabin from dust, the man was putting mud at the bottom of the cabin. I asked him his reason for choosing the concrete mixer without the cabin.

I told him that he could have gotten this equipment fitted with a cabin directly from Atlas. The client said the cabin was cheaper compared to the model we offered. I understood it was an old Indian method of saving money wherever possible.

As I had a closer look at the cabin, I saw it wasn’t welded appropriately, and the plates were thin. The plates were not secured firmly on the ground with a proper foundation. After the inspection, I told the person that the cabin must remain covered during the monsoon season. The panel typically comes with a dedicated dust-proof cover. Nevertheless, it is essential to secure the control panel inside the cabin. It can protect the cabin area with the portable concrete mixer, thereby elongating its lifespan.

I explored various components of the equipment and spoke to the operator. The operator told me that he was happily using this machine for the last two months without any issues. As it was past 9:00 am, I was getting somewhat impatient to get the ready-mix concrete batching plant started so that I could take a video.

Portable concrete mixer at an industrial park

The machine comes fitted with one reversible drum mixer for concrete batching that works like the transit mixer mixing and moves in a clockwise direction. It is a portable concrete mixer that performs the discharging function when moved in the anti-clockwise direction. It has feeder bins that are sized adequately and are of 2×2 type. It means the machine retains the portability factor.

A conveyor is below the aggregate feeder of the machine suspended on the four load cells. The conveyor has the sand, and the aggregates move onto the charging conveyor once weighed. The charging conveyor then moves the same material into the mixer. An option to weigh the materials and add water to the equipment is present. It also allows users to put in more additives. There is a separate hopper for the cement storage, and the cement obtained from bags is present in the cement hopper.

It helps transfer the materials to the cement weigh hopper with the help of the cement screw conveyor. These machines have a control panel that is of the PLC type. It has a 7-inch touchscreen color display that makes the operation user-friendly. The air compressor is on the plant chassis, and it does not take any additional space. As I spoke last with the customer, I knew that they are now planning to work with cement silos to avoid wasting more money on labor.

Conclusion

My trip to the park location was a thoughtful one. I was happy that I could visit the site. I noticed things in person and had an overall positive response from the owner of the plant and the machine operator. Feedback like this always motivates and energizes us to do better and come up with superior-quality products.

More Resources:

- Characteristic Features Of Concrete Batching Plants

- Portable asphalt drum mix plant 90-120 tph Botswana