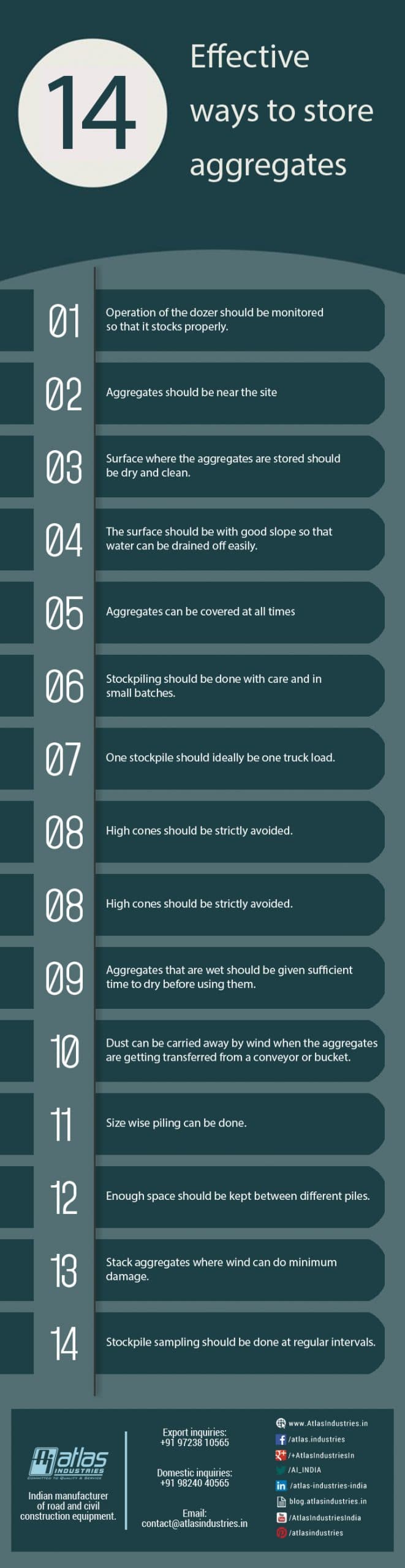

11 ways to store aggregates effectively

2024-12-18

Asphalt and concrete production rely on the aggregate quality. The aggregates form a major part of the end material in asphalt or concrete production. It is important to choose the right kind of aggregates as they directly influence the quality of ready mix concrete and also the quality of hot mix asphalt.

We all know that clean and dry aggregates are essential in both the processes. Excessive wet aggregates will call for compromised product quality. Proper segregation will ensure that aggregates meet the required standards this will ensure that the construction material follows the required production standards. In addition to that proper storage of the aggregates is extremely important in maintaining durability and quality. Proper storage practices will prevent contamination, degradation and even problems related to moisture.

11 Effective Ways to Store Asphalt and Concrete Plant Aggregates

1. Covered Storage Areas:

A simple and effective way to store aggregates is to keep them covered. Using roofs or sheds protects them from rain and weather, reducing moisture and preventing degradation.

2. Segregated Storage:

To prevent cross-contamination, store different types of aggregates in separate compartments / sections. Concrete or steel bins with partitions help keep each type clean and dry.

3. Proper Drainage:

Good drainage is essential for preventing water build up around storage areas. If the storage yard has sufficient slope with a proper drainage it can help in a big manner in keeping the aggregates free from standing water.

4. Use of Tarpaulins:

Using tarps or plastic sheets to cover stockpiles protects asphalt and concrete plant aggregates from rain, snow, and sunlight. This is a practical and straightforward way to achieve this protection.

5. Geotextiles Use:

Geotextiles play a crucial role in lining storage areas and stockpiles. They act as barriers against soil contamination and moisture infiltration. Their durability allows for straightforward installation and maintenance. This makes them ideal choice for protection of aggregates.

6. Stockpile Management:

Proper stockpile management will involve creating well-organized piles with gentle slopes for natural drainage. Avoiding steep slopes is crucial to prevent material segregation and instability. This promotes better quality of aggregates.

7. Windbreaks and Fencing:

Installing windbreaks and fencing around storage areas reduces wind erosion and contamination. This is especially useful for open storage areas where aggregates are exposed.

8. Time-to-time Inspection and Maintenance:

This point cannot be stressed more. Regular inspection and maintenance of storage areas are essential. Checking for contamination, moisture, and material degradation helps maintain aggregate quality. If there is any mishap a timely inspection can take care of it.

9. Proper Loading and Unloading Practices:

Implementing proper loading and unloading practices is essential for preventing material segregation and contamination. Using designated equipment and handling aggregates with care will ensure that aggregates maintain their quality.

10. Dedicated Storage Areas:

Creating separate storage areas for different types of aggregates prevents cross-contamination and ensures each material is stored optimally. This method also simplifies inventory management and quality control.

11. Staff Training and Awareness:

Training staff on the importance of proper aggregate storage and handling practices is essential. Educating employees about potential contamination sources and best practices can help ensure that aggregates are stored and managed effectively.

Conclusion

Properly storing asphalt and concrete plant aggregates is essential to maintain product quality and consistency. These 11 strategies prevent contamination, degradation, and moisture, keeping aggregates in optimal condition. Investing in good storage methods enhances durability and performance, improving construction outcomes and customer satisfaction.

Facts about bitumen tanks...

When we manufacture an asphalt plant, every component is built...

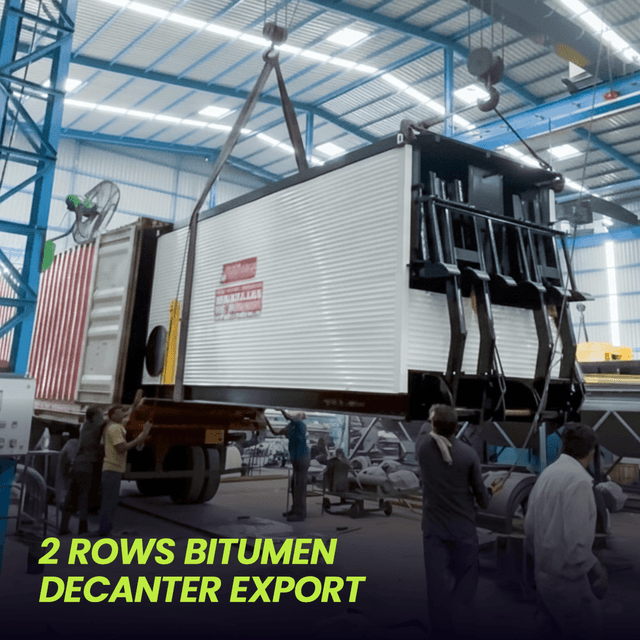

2 rows containerized bitumen decanter...

The export of a two row containerized bitumen decanter offers...

A Comprehensive Guide to Concrete...

Concrete is the main building material on which the reliability...

Understanding the asphalt mixing plant...

At Atlas Technologies Pvt. Ltd. we are committed...