Facts about bitumen tanks

2025-03-18

When we manufacture an asphalt plant, every component is built in-house and assembled at our industry to deliver top-notch quality and precision to our valued customer base. Unlike some manufacturers who outsource critical parts to small fabricators often to meet deadlines—we take full control of the process and offer highly durable machines or any construction equipment. Cutting corners to impress customers is not way we follow to do business and earn revenue; we believe in delivering reliability, consistency, and long-term value.

At Atlas Technologies, we work on straightforward policy—we prioritize delivering the best equipment without compromising on quality. Some customers may find our initial pricing higher than others, but there are some behind this! We do things the right way, ensuring long-term value for your investment. Every denomination, effort, and hour you put into construction equipment should pay off over time. When our equipment outperforms the competition or requires fewer spare parts, you’ll see the difference actually and that what really matters to us.

About Bitumen Tanks

In an asphalt mix plant , some may see the bitumen storage tank as just another component—but for us, it is a critical part of the entire asphalt mixing operation. Bitumen tanks are not just for storing bitumen; these tanks have ability to heat the bitumen stored in it and its pumping station ensures a steady supply to the mixing unit.

However, any malfunction, leakage, or design flaw can result in massive losses. It can also lead to some accident as bitumen is a sensitive material to handle. With bitumen prices constantly rising, you would not like to waste bitumen and this is why getting the asphalt tank design right is essential.

Customization options are available with bitumen tanks. Customers can discuss their requirements with us and we can provide requirements for their needs. It is also important to note that bitumen tank capacity has to be sufficient. The storage has to be adequate meaning that when the bitumen transfer takes place the tanks should have enough capacity to swallow all the incoming bitumen.

Uses of Bitumen Tanks for Different Products

- Asphalt batch mix plant

- Asphalt drum mix plants

- Counter-flow asphalt mixers

- Mobile asphalt plants with mobile bitumen tanks

- Bitumen drum decanters for additional storage facility of bitumen

- Storage and transportation of bitumen from one place to another

Direct vs. Indirect Heating in Bitumen Storage Tanks: Key Differences

Bitumen storage tanks come in two types. One is direct heating and another is indirect heating. Both these types of bitumen storage tanks offer customers the flexibility to select between the two as per their current requirements.

In direct heating tanks, a burner is directly attached to the tank. The burner’s flame heats a network of pipelines at the tank’s base, which then melts the bitumen efficiently.

On the other hand, in indirect heating tanks, a separate hot oil heater is used. This system has a burner and internal coils that circulate heated oil to the tank. As the hot oil flows in, it transfers heat to the bitumen, and when it returns to the heater, it has cooled slightly. The heater then raises the oil’s temperature before recirculating, ensuring a continuous heating process.

The great part? These bitumen tanks are also available as mobile or stationary. They are also available with or without pumping station.

If you are looking for Bitumen tanks for sale, approach Atlas Technologies. We’re leading manufacturers of asphalt storage tanks. We manufacture these tanks in two shapes: O shaped and U shaped. Both these tanks have their own advantages.When dealing with bitumen in barrels, U-shaped tanks are often the go-to choice. Their flat top provides a stable surface, making it easier to walk on while managing the unloading process. On the other hand, O-shaped tanks are favoured by many for their sleek design. They also come with a small platform, offering just enough space for a person to walk and efficiently unload bitumen barrels. The choice ultimately depends on whether functionality or aesthetics takes priority in your operation.The largest tank that can fit in a 40 ft. container holds 40 tons. If you need a bigger asphalt tank, larger capacity options are also available for purchase.From choosing the right capacity of bitumen storage to the right placement of bitumen tanks it is important to plan well in advance. They have to be sourced from a reputed manufacturer. There should be no compromise on the safety parameters. The regular maintenance for these bitumen tanks have to be done which will ensure long life and less chances of any accident. For more details, get in touch with us now!

Facts about bitumen tanks...

When we manufacture an asphalt plant, every component is built...

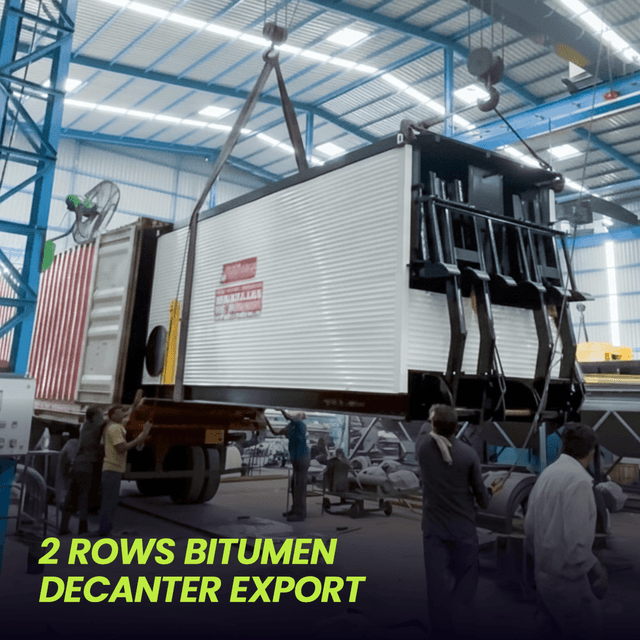

2 rows containerized bitumen decanter...

The export of a two row containerized bitumen decanter offers...

A Comprehensive Guide to Concrete...

Concrete is the main building material on which the reliability...

Understanding the asphalt mixing plant...

At Atlas Technologies Pvt. Ltd. we are committed...